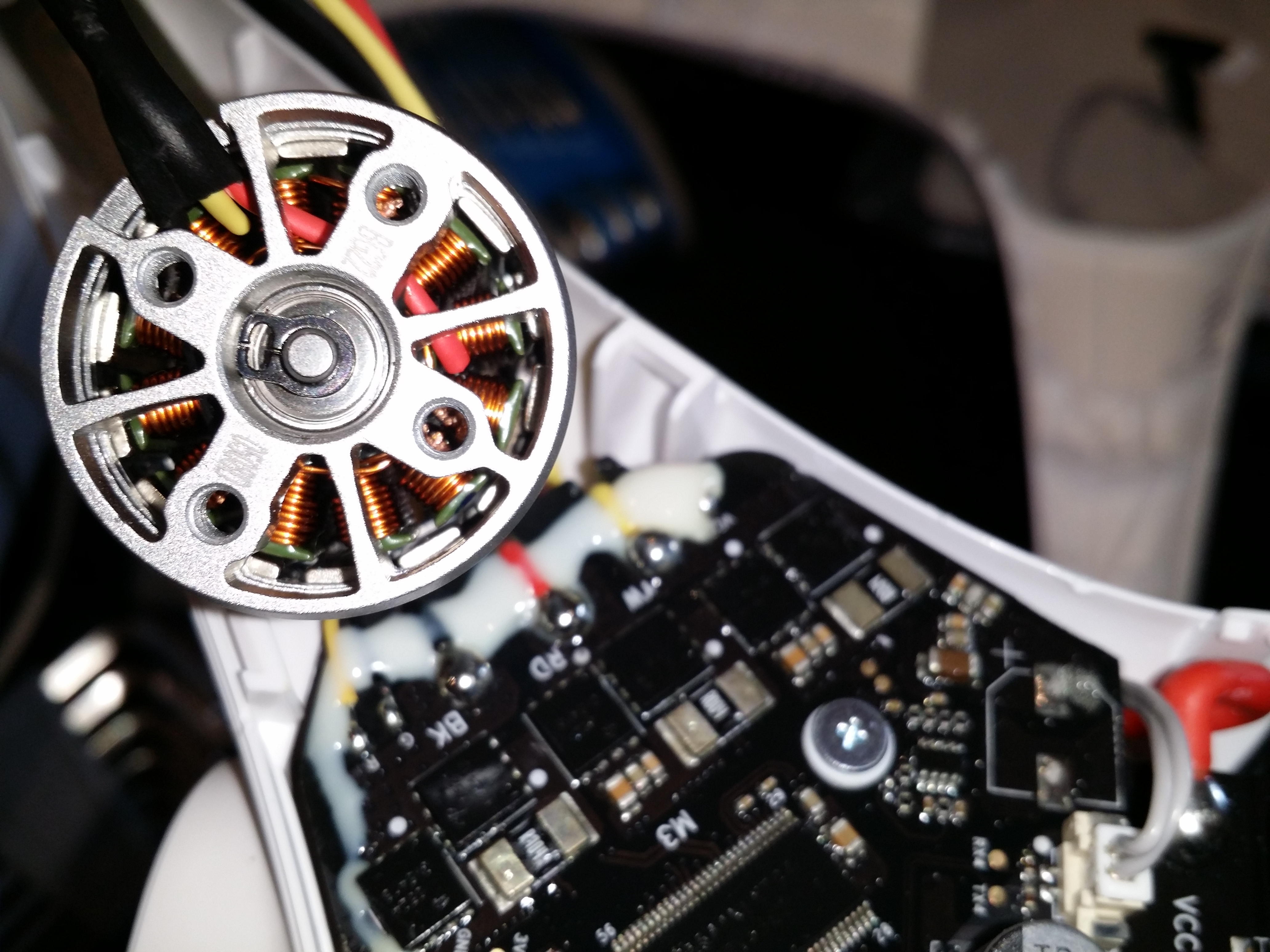

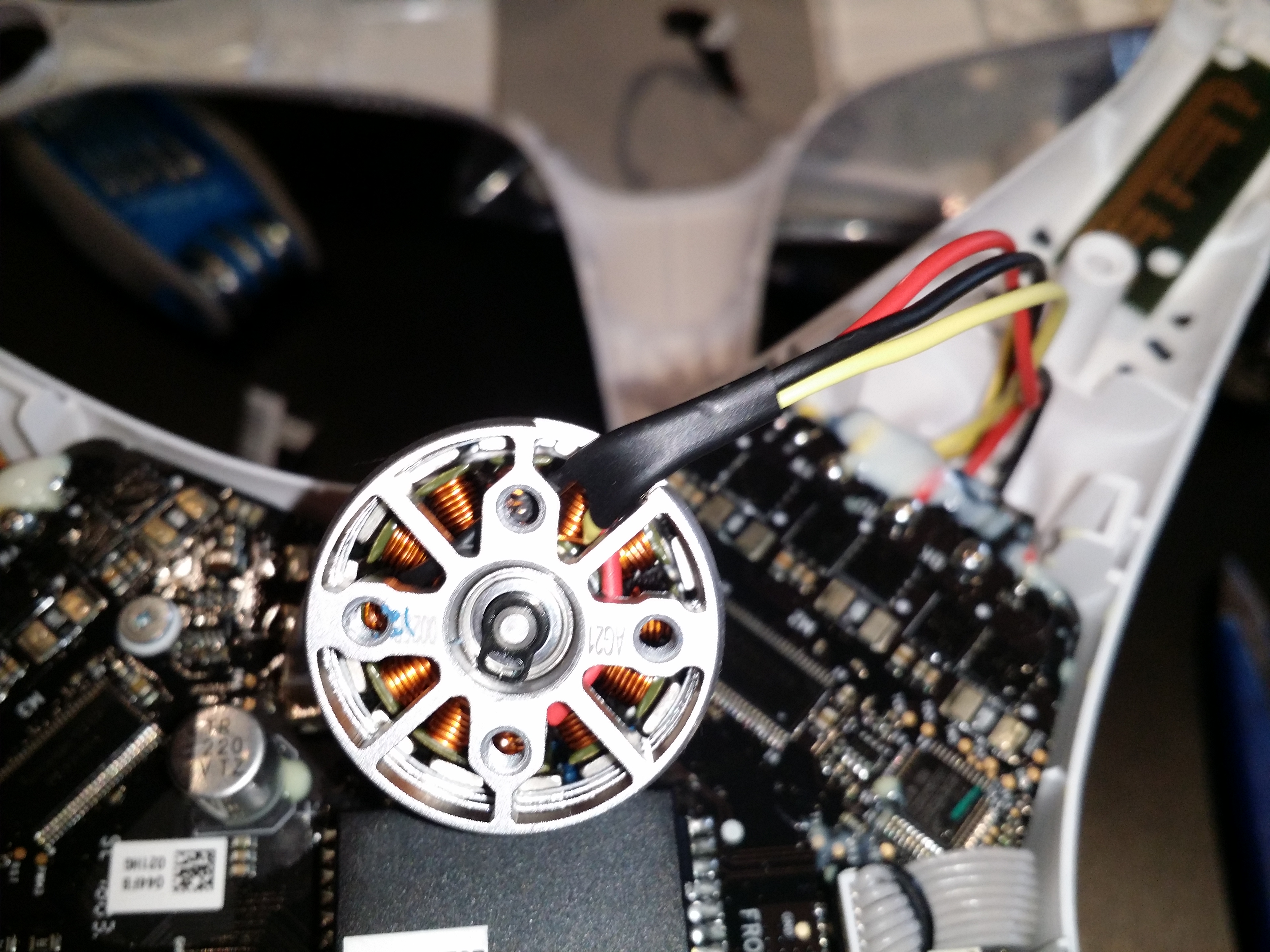

In an unnecessary rush I've made a stupid error and killed my P3A - persistent ESC errors despite all the standard troubleshooting. The story is: after some routine maintenance I used the wrong screws (too long) to mount the motors, I assume the majority of the damage was done when trying to power up the motors (which is did more than once or twice....I know, colossally dumb) and they were jammed in place by the screws poking up into the housing.

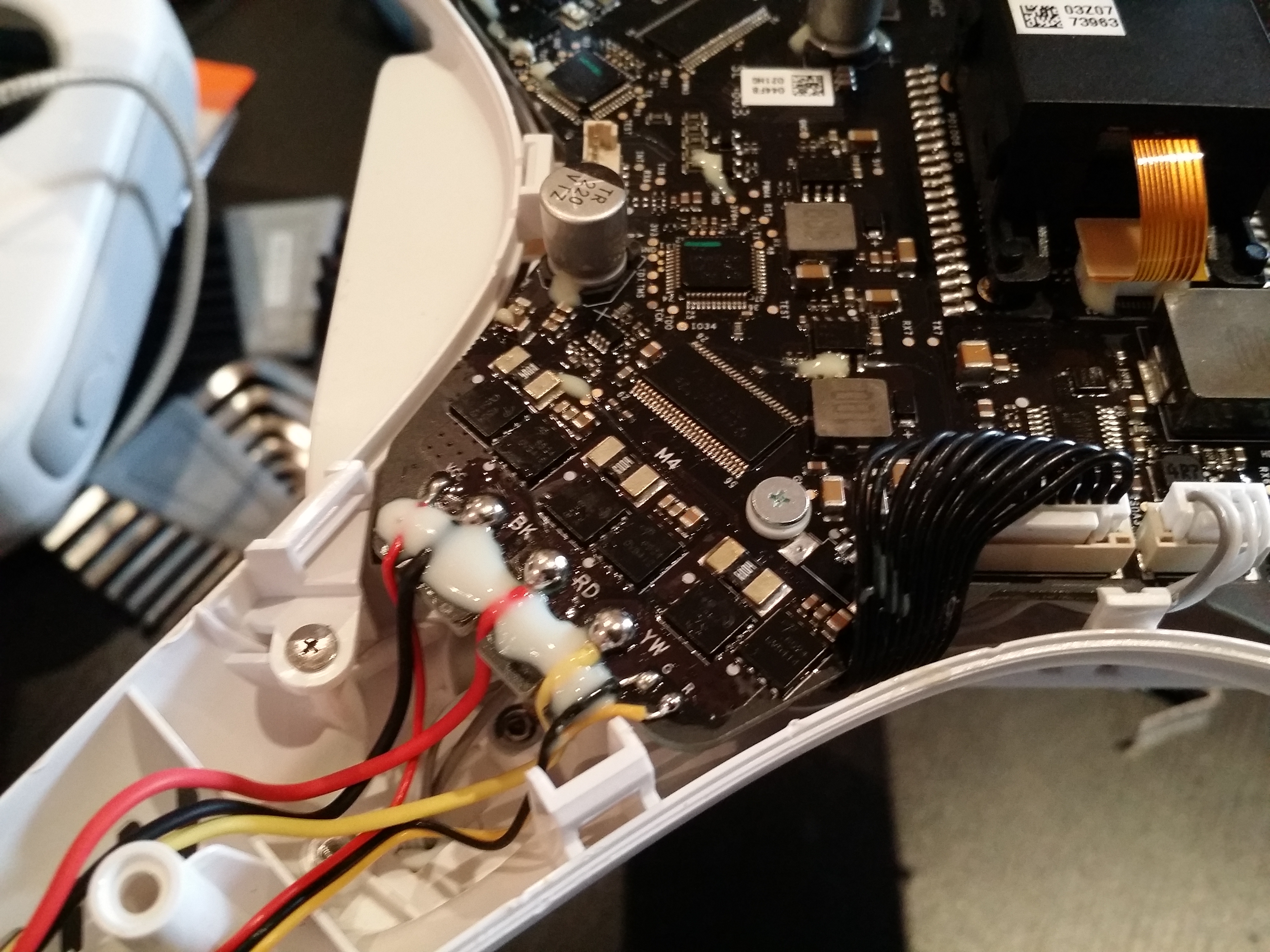

Anyways I'm looking at my options for repair & replacement and I've read that the P3A centreboard is integrated with the ESC's on the P3's - so if I can confirm that I've only destroyed the motors I could save myself some cash as full board replacement looks pretty pricey.

Any advice out there for how to diagnose the extent of damage to the motors & ESC/centreboard? I assume visual inspection will be insufficient, where / what measurements can I use to confirm failure at different points?

Thanks in advance - this forum (and the community at large) has been really useful so far!!

Anyways I'm looking at my options for repair & replacement and I've read that the P3A centreboard is integrated with the ESC's on the P3's - so if I can confirm that I've only destroyed the motors I could save myself some cash as full board replacement looks pretty pricey.

Any advice out there for how to diagnose the extent of damage to the motors & ESC/centreboard? I assume visual inspection will be insufficient, where / what measurements can I use to confirm failure at different points?

Thanks in advance - this forum (and the community at large) has been really useful so far!!