Hello, all. New member here.

There's certainly no small number of "crash" threads here on PhantomPilots, but I thought I'd add my own story from a different perspective: I'm starting off as someone who found a crashed P3P on Facebook Marketplace and felt the challenge to make it fly again for as cheaply as possible (much of my life has been spent toying with electronics and working as a system administrator, so I find a lot of enjoyment in solving computer problems and working with electronics and tools). In going through the motions of learning about this unit, the culture surrounding it, and DJI's philosophies, I've learned a good deal which might be useful for other enthusiasts who come across damaged or otherwise unresponsive equipment.

It began on a Monday afternoon; I took a 2-hour backroads country drive to Kansas City and bought the still-unsold Professional for $60 from an up-and-coming cinematographer. The gentleman wasn't able to provide much backstory on the unit as he had purchased it for parts off someone else. The evidence was unmistakable, however, that this unit fell fast and hard. Here are a few photos from his original ad posting:

Initial Examination & Drone Repair

At this point, I knew nothing about the Phantom 3 Professional other than it still serves as the "gold standard" of private quadcopter-format drones, but some online research quickly helped reveal how the various parts of this device operate. Before doing anything, a visual inspection had to take place and unfortunately I don't have those early photos accessible at the moment. It's pretty clear from the above photos that:

And there-in was my first mistake--not a fatal one, but certainly in practice. Never attempt to run power to a damaged device until AFTER you've inspected it thoroughly. There's too much of a risk that something might short out or cause further damage, possibly even a fire. Other than removing the entire camera and gimbal assembly due to its erratic state, I didn't think the situation through and powered the unit off of 12VDC only to receive a loud and steady stream of prolonged beeps. I got lucky nothing was further damaged and you'll see why shortly, but let's first look at some photos of the unpowered camera's condition:

and inside...

You can't really see it in these small photos, but the CNC aluminum parts and motors absorbed much of the fall after the landing gear cracked. At least half need replacement. Worse though, is that the main logic board still took a sharp blow from the yaw arm's elbow when the motor post bent. In the first of the above three photos, an SMD capacitor was pressed into plastic cover and was ripped off the PCB. In the second, you might be able to see where it belonged, but another spot is vacant and a few pieces have shifted the traces from the immense pressure. In the third photo, that's the shattered BGA on the opposite side of the PCB (look for the three cracks leading out from the center). I've never seen that kind of damage before.

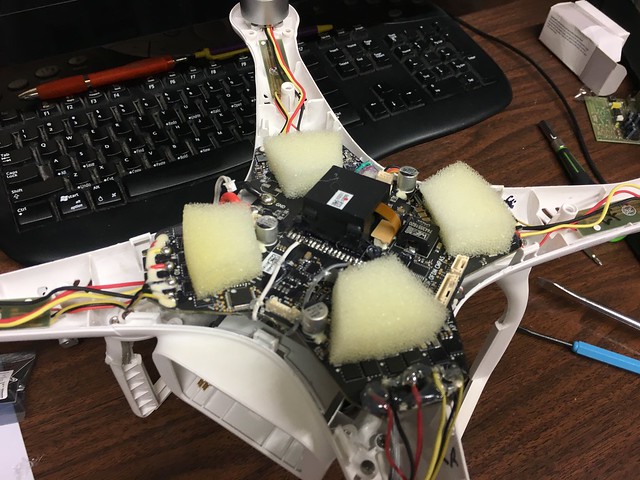

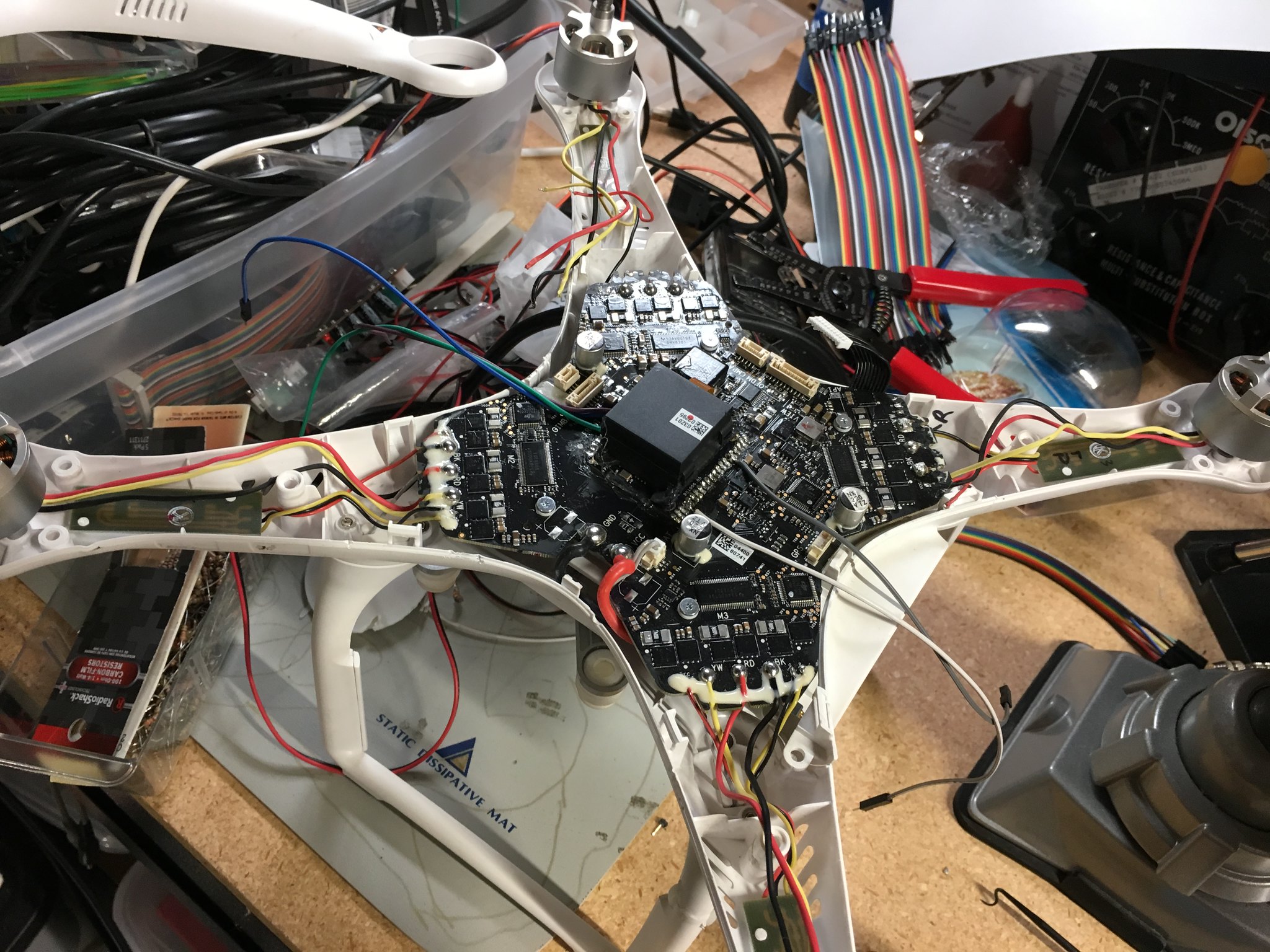

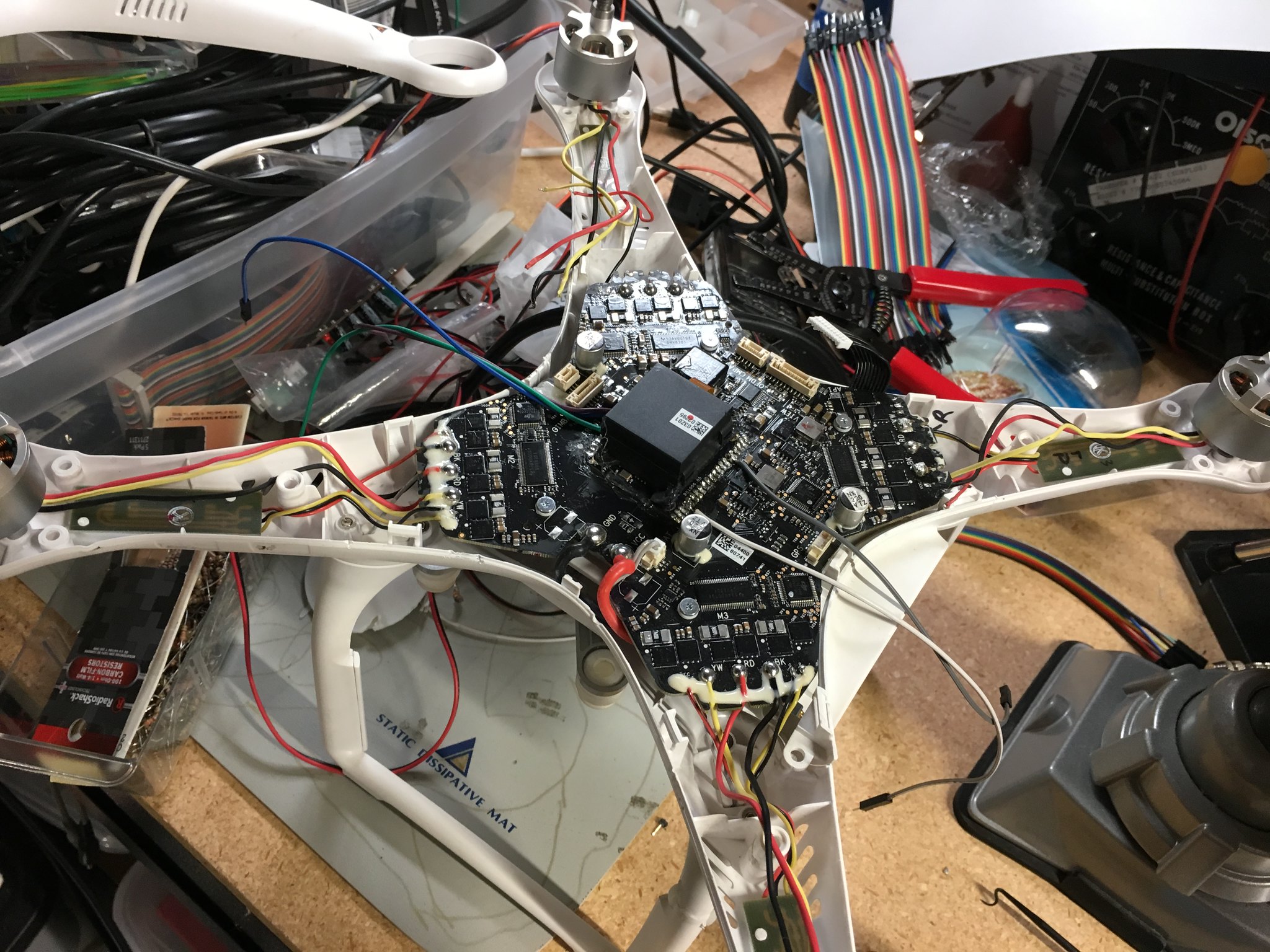

After the original powered test, I opened the main shell up to find much more substantial damage to the drone. From the markings on case edges, it's clear I wasn't the first one to peer inside. Though almost everything appeared okay to the eye, one piece was clearly out of place: The main controller. The center piece is soldered in place and sits on a very shallow and thin plastic ledge, one of the worst design decisions I've ever seen. The main drone PCB also is supposed to attach to four floating screw mounts which absorb some of vibration from landing, but in a case like this they simply cracked their mounts and the main controller tore free of every single solder point. I don't have that early photo handy, but here's how the device looked after substantial resoldering and wire runs (where the pads were torn off one side or the other):

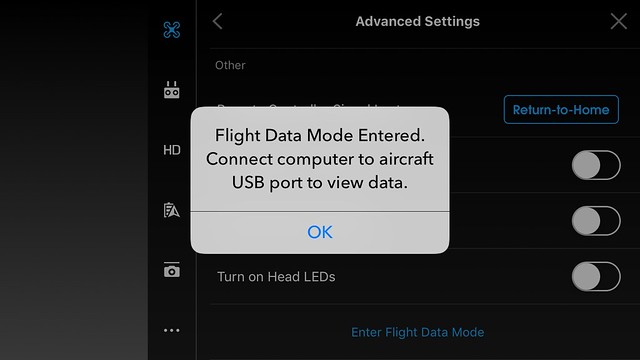

I made liberal use of hot glue for vibration damping on wires and to better hold the center core in place from any future shock. While performing this sort of surgery, I also took advantage of the opportunity to make a raw backup of the SD card firmware in case any log data was sitting on it. Here's the process used on my Mac:

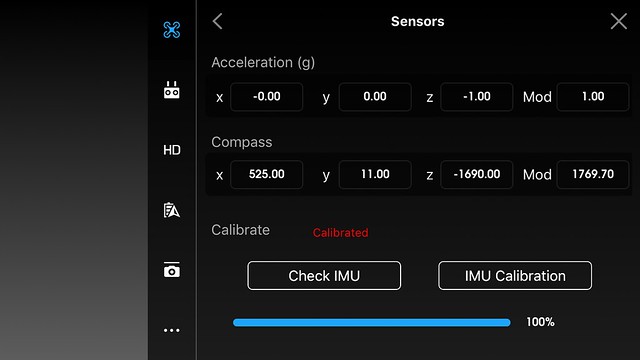

With all the obvious repairs made to the main unit, minus the camera and gimbal, I was able to power it up again. This time around, it went through its self-test and registered as a valid DJI USB device on my Mac. Here's a video of that startup and obnoxious beeping:

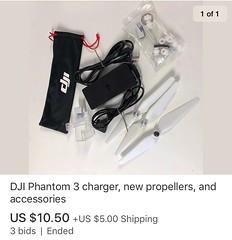

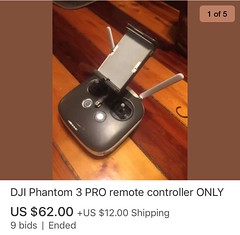

The above progress was motivating enough that I started buying cheap accessories off eBay:

A few quick notes: The lens cover screw in place and resolved the issue of the broken glass; the controller was marked lower than most broken controllers thanks to someone painting it; the case is in great shape for the cost; the stickers are terrible...they curl up and rip because they're paper-based; the charger, extra parts, and propellers was a great save as opposed to buying each chunk separately.

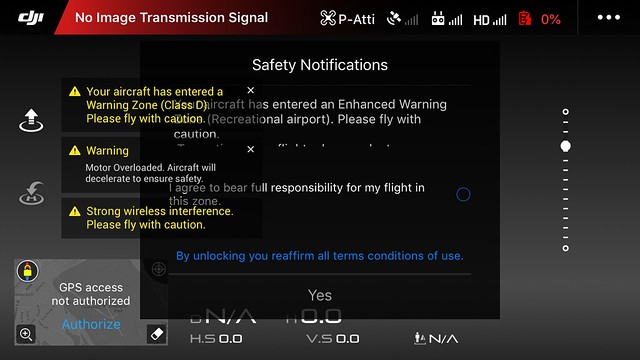

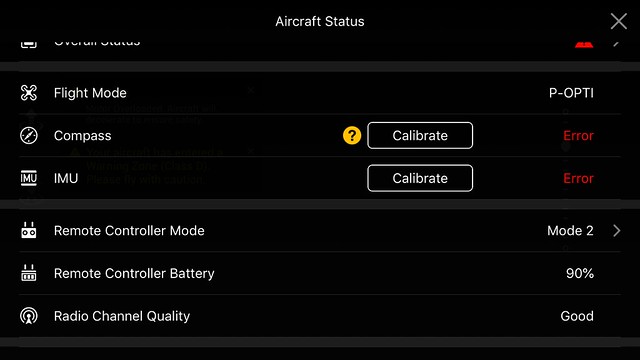

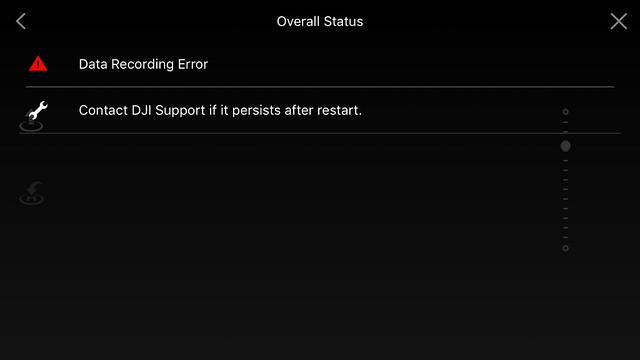

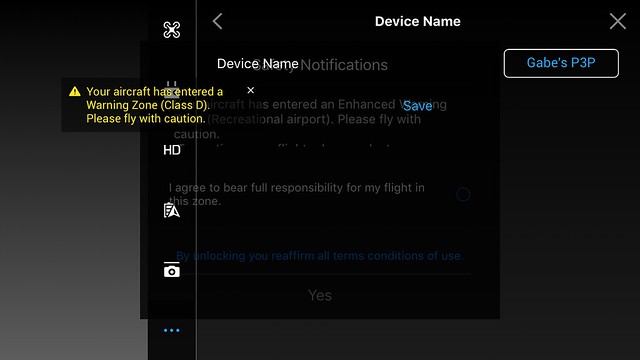

At this point I was awaiting the parts in full, but to my luck the controller shipped and was delivered within 72 hours. Up next is my experience with the DJI Go app and syncing, both fairly horrific experiences with a happy ending...and a clue regarding the original owner!

There's certainly no small number of "crash" threads here on PhantomPilots, but I thought I'd add my own story from a different perspective: I'm starting off as someone who found a crashed P3P on Facebook Marketplace and felt the challenge to make it fly again for as cheaply as possible (much of my life has been spent toying with electronics and working as a system administrator, so I find a lot of enjoyment in solving computer problems and working with electronics and tools). In going through the motions of learning about this unit, the culture surrounding it, and DJI's philosophies, I've learned a good deal which might be useful for other enthusiasts who come across damaged or otherwise unresponsive equipment.

It began on a Monday afternoon; I took a 2-hour backroads country drive to Kansas City and bought the still-unsold Professional for $60 from an up-and-coming cinematographer. The gentleman wasn't able to provide much backstory on the unit as he had purchased it for parts off someone else. The evidence was unmistakable, however, that this unit fell fast and hard. Here are a few photos from his original ad posting:

Initial Examination & Drone Repair

At this point, I knew nothing about the Phantom 3 Professional other than it still serves as the "gold standard" of private quadcopter-format drones, but some online research quickly helped reveal how the various parts of this device operate. Before doing anything, a visual inspection had to take place and unfortunately I don't have those early photos accessible at the moment. It's pretty clear from the above photos that:

- The camera gimbal is mangled

- The camera base is shattered

- The lens debris glass cover is shattered

- An antenna mount is knocked loose

- A cracked landing leg

- A cracked screw post behind one motor

- Two surface mount cable sockets were ripped off

- One of the camera's rubber absorbers was ripped

And there-in was my first mistake--not a fatal one, but certainly in practice. Never attempt to run power to a damaged device until AFTER you've inspected it thoroughly. There's too much of a risk that something might short out or cause further damage, possibly even a fire. Other than removing the entire camera and gimbal assembly due to its erratic state, I didn't think the situation through and powered the unit off of 12VDC only to receive a loud and steady stream of prolonged beeps. I got lucky nothing was further damaged and you'll see why shortly, but let's first look at some photos of the unpowered camera's condition:

and inside...

You can't really see it in these small photos, but the CNC aluminum parts and motors absorbed much of the fall after the landing gear cracked. At least half need replacement. Worse though, is that the main logic board still took a sharp blow from the yaw arm's elbow when the motor post bent. In the first of the above three photos, an SMD capacitor was pressed into plastic cover and was ripped off the PCB. In the second, you might be able to see where it belonged, but another spot is vacant and a few pieces have shifted the traces from the immense pressure. In the third photo, that's the shattered BGA on the opposite side of the PCB (look for the three cracks leading out from the center). I've never seen that kind of damage before.

After the original powered test, I opened the main shell up to find much more substantial damage to the drone. From the markings on case edges, it's clear I wasn't the first one to peer inside. Though almost everything appeared okay to the eye, one piece was clearly out of place: The main controller. The center piece is soldered in place and sits on a very shallow and thin plastic ledge, one of the worst design decisions I've ever seen. The main drone PCB also is supposed to attach to four floating screw mounts which absorb some of vibration from landing, but in a case like this they simply cracked their mounts and the main controller tore free of every single solder point. I don't have that early photo handy, but here's how the device looked after substantial resoldering and wire runs (where the pads were torn off one side or the other):

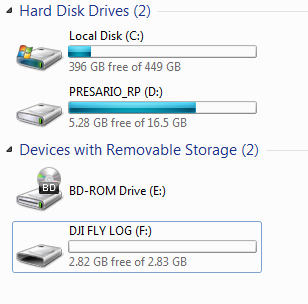

I made liberal use of hot glue for vibration damping on wires and to better hold the center core in place from any future shock. While performing this sort of surgery, I also took advantage of the opportunity to make a raw backup of the SD card firmware in case any log data was sitting on it. Here's the process used on my Mac:

- Backup:

- Plug card into Mac

- df -h to see which device the card is mounted as

- diskutil unmountDisk /dev/disk9 (ex)

- sudo dd if=/dev/disk9 of=~/Desktop/BACKUP.dimg

- Restore:

- Plug card into Mac

- df -h to see which device the card is mounted as

- diskutil unmountDisk /dev/disk9 (ex)

- sudo dd if=~/Desktop/BACKUP.img of=/dev/disk9

- Use a partition application to grow the partition as necessary.

With all the obvious repairs made to the main unit, minus the camera and gimbal, I was able to power it up again. This time around, it went through its self-test and registered as a valid DJI USB device on my Mac. Here's a video of that startup and obnoxious beeping:

The above progress was motivating enough that I started buying cheap accessories off eBay:

A few quick notes: The lens cover screw in place and resolved the issue of the broken glass; the controller was marked lower than most broken controllers thanks to someone painting it; the case is in great shape for the cost; the stickers are terrible...they curl up and rip because they're paper-based; the charger, extra parts, and propellers was a great save as opposed to buying each chunk separately.

At this point I was awaiting the parts in full, but to my luck the controller shipped and was delivered within 72 hours. Up next is my experience with the DJI Go app and syncing, both fairly horrific experiences with a happy ending...and a clue regarding the original owner!

Last edited: