- Joined

- Mar 8, 2016

- Messages

- 624

- Reaction score

- 258

- Age

- 67

Hey all,

My new gimbal / camera replacement package is coming today, so I've been working on the removing the old parts this morning. The gimbal removal was simple, especially with this helpful video (though I had to break one of the plastic gimbal clips).

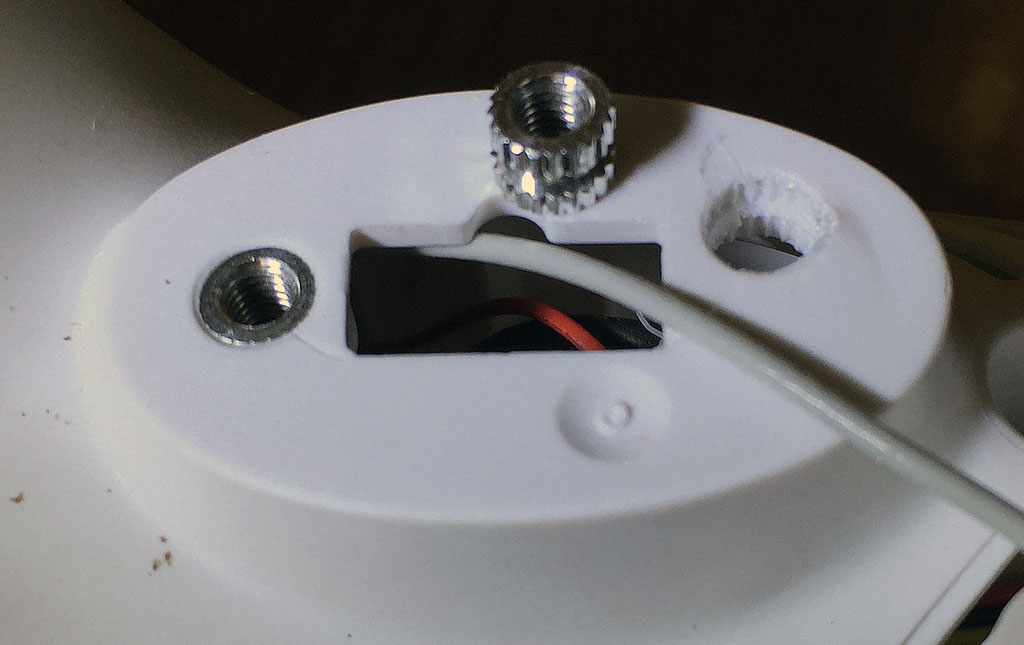

While waiting, I'm looking at the other part in need of repair, a landing gear. I've attached two images below. The first is of the healthy screw-holes for one side. The second image is the other side, in which the inset nut has come out from the shell. Rather than replace the shell, I'd like to just glue that part back in. Is there an appropriate adhesive to use for this?

Also on the 2nd image you might see the crack near the other nut going toward the bottom-left corner of the center opening, even though that nut is still in the shell-hole. Can the same adhesive be applied to that crack to ensure that it stays put? Note: I typically hand-catch land.

Thanks for all tips,

Chris / Speck

My new gimbal / camera replacement package is coming today, so I've been working on the removing the old parts this morning. The gimbal removal was simple, especially with this helpful video (though I had to break one of the plastic gimbal clips).

While waiting, I'm looking at the other part in need of repair, a landing gear. I've attached two images below. The first is of the healthy screw-holes for one side. The second image is the other side, in which the inset nut has come out from the shell. Rather than replace the shell, I'd like to just glue that part back in. Is there an appropriate adhesive to use for this?

Also on the 2nd image you might see the crack near the other nut going toward the bottom-left corner of the center opening, even though that nut is still in the shell-hole. Can the same adhesive be applied to that crack to ensure that it stays put? Note: I typically hand-catch land.

Thanks for all tips,

Chris / Speck