Here is an interesting issue: Factory direct and third party purchased blades for Phantom 4 are not finished properly. The trailing edges are rough and have a definite "ridge" along the trailing edge on most of them . . some worse than others but you can feel it with your finger or thumb by running it over the surface in the direction of the normal airflow. I thought I was just imagining it at first but took some closeups and it's really there. . . more exaggerated on some but it's on every one I've purchased so far. This makes them less efficient, adds noise and wastes a bit battery energy. There are 8 turbulence generating surfaces like that on set of P4 blades.

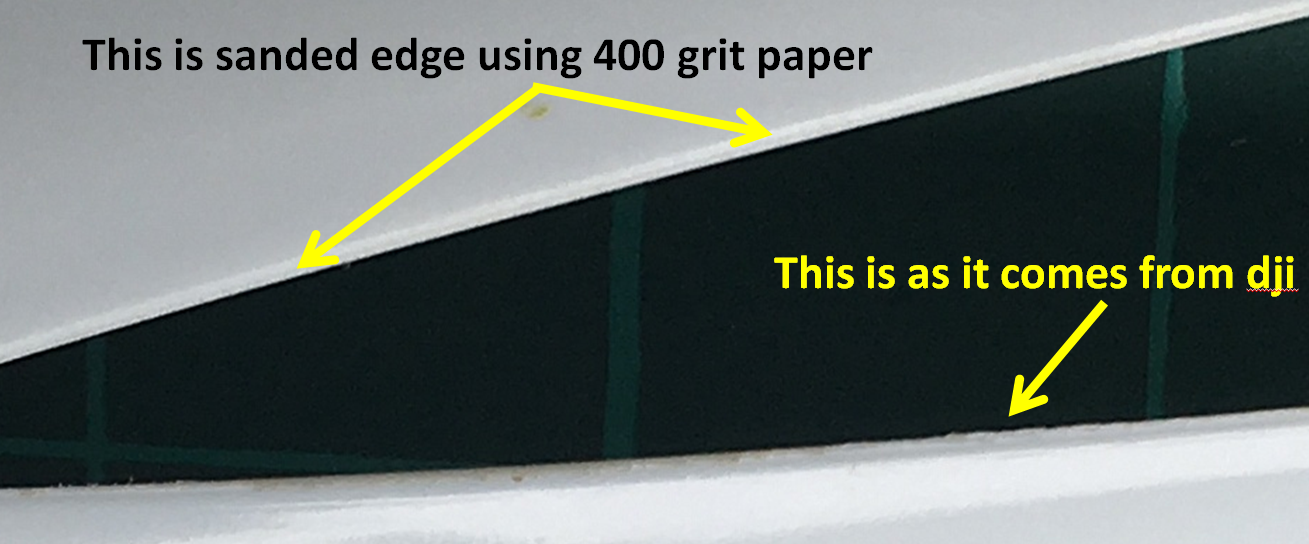

So, I took some 400 sandpaper and just "brushed" them off in the direction of airflow gently along the trailing edge from root to tip. Does not take much . . go gently and feel it with the edge of your thumb after each pass. Drag in the direction of the airfoil till you cant feel it any more. It should only take 2-3 light passes. ( see comparison photos)

RESULT: quieter sound, and can't prove it but seems really quick and my fastest speed is logged as 56.38mph and before the best I saw was 47.73. Not a valid comparison really (just comparing 2 flights) . . but it does seems faster.

So, I took some 400 sandpaper and just "brushed" them off in the direction of airflow gently along the trailing edge from root to tip. Does not take much . . go gently and feel it with the edge of your thumb after each pass. Drag in the direction of the airfoil till you cant feel it any more. It should only take 2-3 light passes. ( see comparison photos)

RESULT: quieter sound, and can't prove it but seems really quick and my fastest speed is logged as 56.38mph and before the best I saw was 47.73. Not a valid comparison really (just comparing 2 flights) . . but it does seems faster.