We should start a thread here with all the home made mod one can make with the lack of parts availability for the P3 now, like from dataway

http://www.phantompilots.com/thread...-weight-updated-with-comparison-photos.42196/

I was doing a lot of crash testing very close to buildings, see my post

http://www.phantompilots.com/threads/ultrasonic-sensor-error.40601/page-6#post-377088

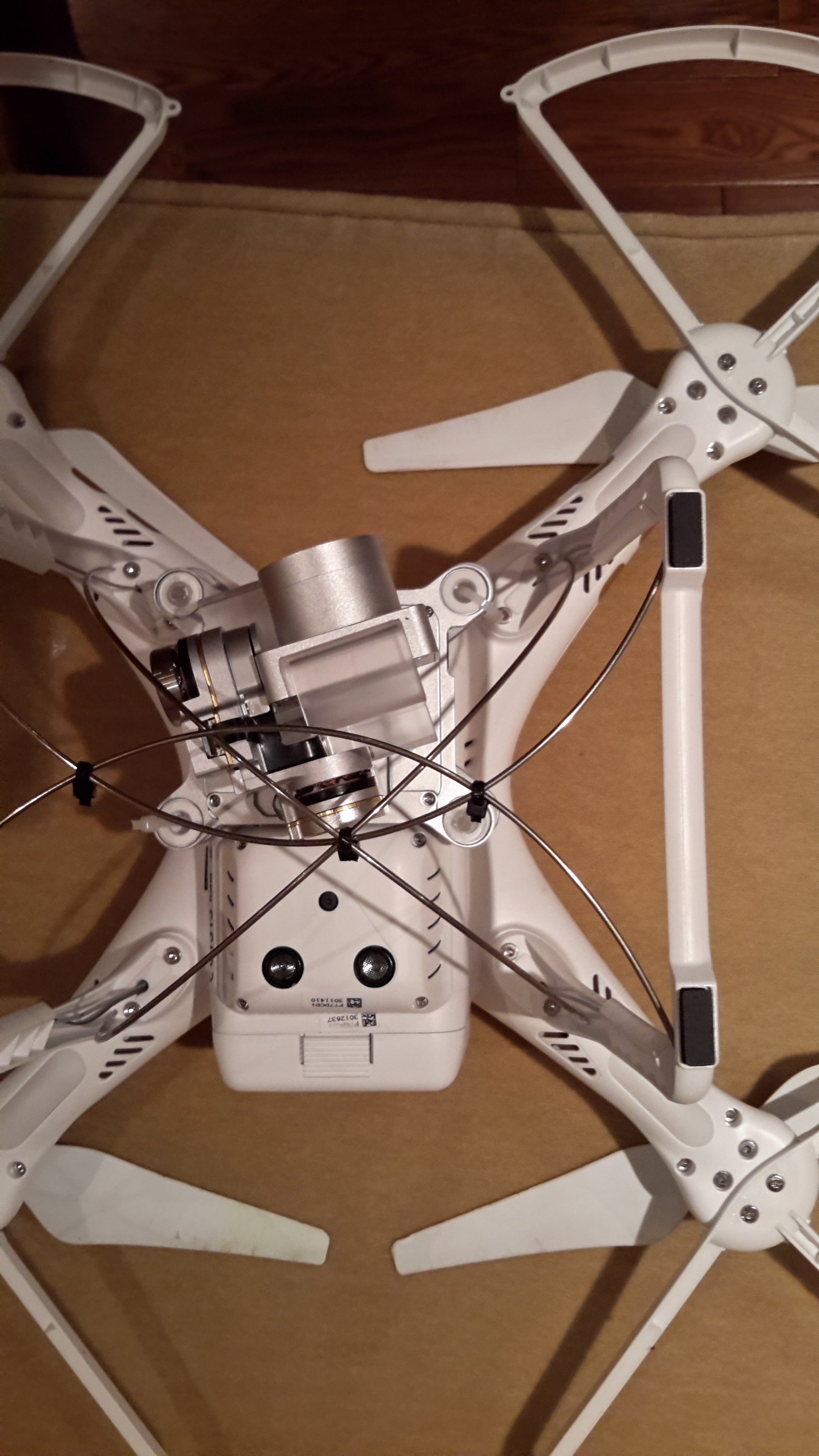

so I fabricated a gimble protector with a few length of .0625 stainless mig welding wire in about 5 mintues. I have not done effect on long range signal test on the CAGE yet, but it stays on perfectly and it will not even budge with a 10 lb weight on it. It should not affect range since it is on the bottom and inside of the sensors.

The natural arch fit the turning arc of the gimble perfectly so there is no interference whatsoever.

I use 4 arches for maximum protection with a total weight of 16g but you can get away with 3 or even 2 to cut down to 8 grams. It also gives the landing antenna a lot more rigidity.

http://www.phantompilots.com/thread...-weight-updated-with-comparison-photos.42196/

I was doing a lot of crash testing very close to buildings, see my post

http://www.phantompilots.com/threads/ultrasonic-sensor-error.40601/page-6#post-377088

so I fabricated a gimble protector with a few length of .0625 stainless mig welding wire in about 5 mintues. I have not done effect on long range signal test on the CAGE yet, but it stays on perfectly and it will not even budge with a 10 lb weight on it. It should not affect range since it is on the bottom and inside of the sensors.

The natural arch fit the turning arc of the gimble perfectly so there is no interference whatsoever.

I use 4 arches for maximum protection with a total weight of 16g but you can get away with 3 or even 2 to cut down to 8 grams. It also gives the landing antenna a lot more rigidity.