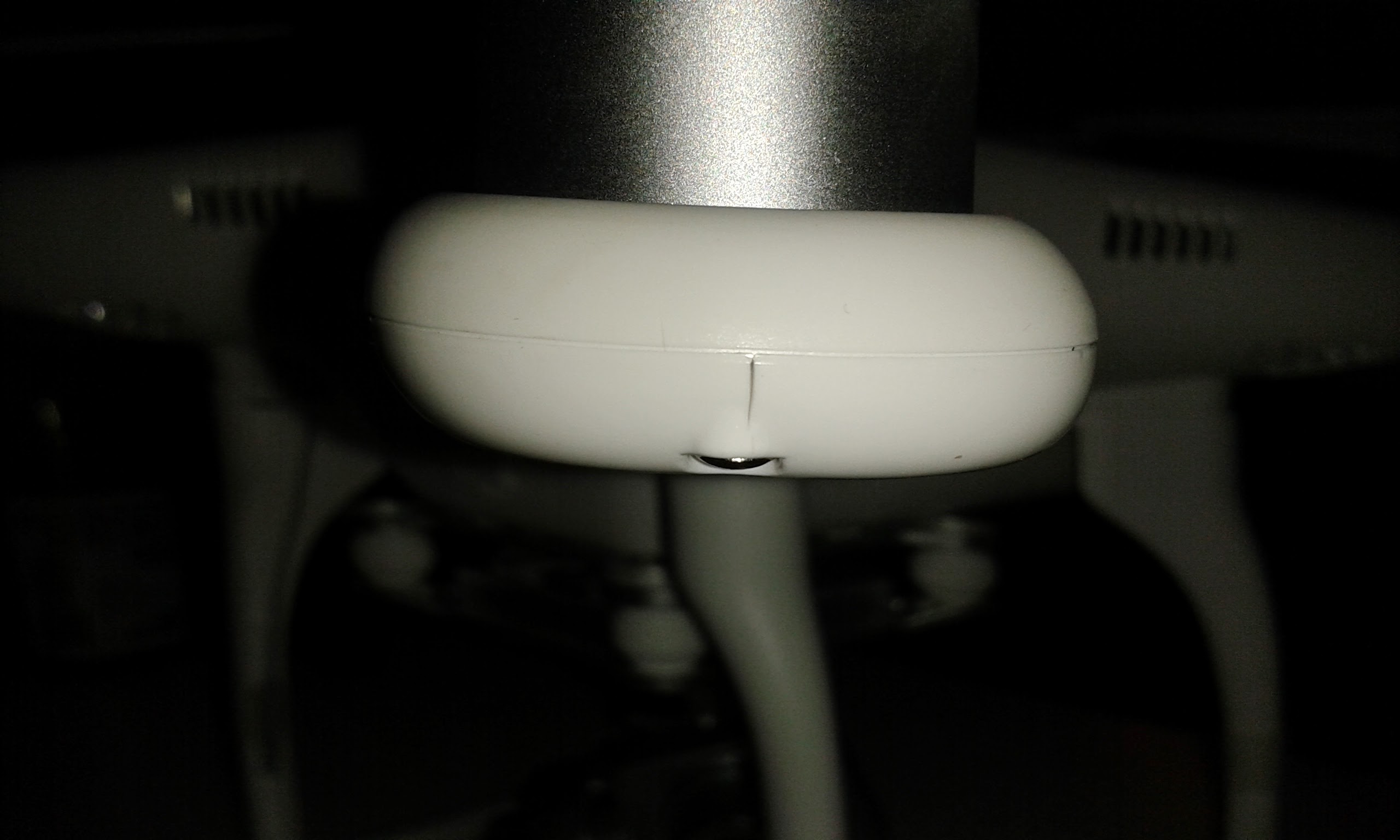

Retired my old v2 and took a new in box v3 I had sitting around. Four days and about twently crash free flights later, low and behold, same old stress cracks I've seen in every other phantom I've owned. I'm bummed. Hopefully they solved this pesky little phantom problem on the p3.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brand new v3, brand new crack

- Thread starter bighi

- Start date

- Joined

- Apr 14, 2015

- Messages

- 99

- Reaction score

- 23

N017RW

Premium Pilot

I would say the same but there was no crack there yesterday. I retired my v2 back a few days ago when a massive crack opened up on the top of the shell surrounding the motor. So I took this brand new v3 out of the box, looked at the shell carefully for cracks and nothing. Brand new after all. But I was curious to see if maybe, just maybe they used a better plastic on the v3. But nah, four days of flying later, crack. Same old brittle stuff. Yeah, maybe that screw was too tight and gave up a ghost. But still, I'm getting tired of fixing cracks. There are plenty of complaints out there for issues I've never experienced on four phantoms. My never crashing pretty much ensured I never had gimbal trouble or things of that nature. Same with always ensuring I had full GPS lock and home point set. But this **** stress cracking problem I'm starting to get sick and tired of. I'm tired of repairing cracks on my never crashed phantoms. I will continue buying DJI products, but I hope those guys improved the shell on the p3.

I don't know if I recall seeing many, if any other threads of users with cracks like that. Let alone on every unit they own.

I'm wondering if there is some link to something your doing, how you store them, or something that is causing it. Might not even be something you're aware of.

I'm wondering if there is some link to something your doing, how you store them, or something that is causing it. Might not even be something you're aware of.

They were never transported in any way and are stored on top of my dining room table. They are always flown in regular temps. Between 70 and 85 Fahrenheit.I don't know if I recall seeing many, if any other threads of users with cracks like that. Let alone on every unit they own.

I'm wondering if there is some link to something your doing, how you store them, or something that is causing it. Might not even be something you're aware of.

do you use those snap on, snap off prop guards?

True. He could be tightening them on too tight.

For this to be happening on every unit you own that quickly. You're doing something wrong.

My new P2V+ V3 had these on all four corners after only a few flights, mostly hand-catching. Seems kinda funny to have to superglue something you just paid £850 for, but there you go.

It's great if your phantom doesn't have these, but the OP is not an isolated case.

It's great if your phantom doesn't have these, but the OP is not an isolated case.

Nope, no prop guards guys. Never felt the need for them since I haven't crashed any phantom yet. Anyway, this is the type of flying I do. Nothing extreme. Certainly no different than any dji advertising video I've seen.

My new P2V+ V3 had these on all four corners after only a few flights, mostly hand-catching. Seems kinda funny to have to superglue something you just paid £850 for, but there you go.

It's great if your phantom doesn't have these, but the OP is not an isolated case.

Definitely not an isolated case. Again, I venture to say that if half the forum members would look they would find cracks around the motor area. I posted this on the P3 section to see if anybody is experiencing this on the P3 section and I got the same surprises. Then one guy with a P3 goes and look at his P2 and, low and behold, cracks. Now he is asking me how to apply crazy glue. This may have been solved on the P3 but then again, nobody even noticed on the P2 except for a few of us who actually bothered to look. Instead they complain about fragile gimbals of which I haven't broken one in any phantom. The key being not to crash. But the cracks happen regardless of how much care I take. Unless DJI intends their quads to be flown slowly around some structure with prop guards. If that's the case, I wish they would let us know because when they create P3s with so much range, what kind of flying is implied other than the kind I'm doing?

Just a thought, but have you balanced your props? If not, cracks could be caused by vibration. I've had my

Vision + V3 for about 3 months, flown almost every day in all sorts of weather, never crashed or hard landing and I don't have any sign of cracks at all. Having many years flying RC helicopters, I know just how much damage vibration can cause so my Phantom props were balanced before my first flight (and checked regularly).

Vision + V3 for about 3 months, flown almost every day in all sorts of weather, never crashed or hard landing and I don't have any sign of cracks at all. Having many years flying RC helicopters, I know just how much damage vibration can cause so my Phantom props were balanced before my first flight (and checked regularly).

Yup, they were balanced. But maybe DJI should mention on the instructions something akin to "we highly recommend balancing the props in order to reduce the chance of stress cracks on fuselage." And if the shells were just one mil thicker around those high stress parts the problem would go away. But anyway, there must be some plastic quality control issues at play which I'm curious to see if they go away on the P3.

I quite agree, DJI should draw attention to the importance of balancing props. As to quality control, it seems this is something DJI really needs to improve upon, it seems to be a matter of pot luck whether you get a good one or a not so good one.

Retired my old v2 and took a new in box v3 I had sitting around. Four days and about twently crash free flights later, low and behold, same old stress cracks I've seen in every other phantom I've owned. I'm bummed. Hopefully they solved this pesky little phantom problem on the p3.

View attachment 18414

Just today noticed a crack exactly like yours on my still new P2 (just 10 hand catching flights). I did check all the arms when I first got it, as my P1 developed them as well. That crack on the P2 was not there at that point. I also balance the props and in the case of the P2 have not touched the screws or opened it up. So most certainly a weak part of the Phantom design and I bet the P3 will have it as well!

Do you have a picture of it? I have said before that this happens much more often than people think. This frankly, is ******** in something costing this much money and without a crash. I ordered a P3 and should receive it next week. Let's see how many flights I get in before I break out the super glue.

When these are assembled, if the 4 small screws (at the end of each arm) are tightened FIRST - and then all of the others screws are tightened SECOND, all 4 small screws will have excess pressure on them. Make sure when you remove the cover that you remove the 4 small screws first - and that when you reinstall the cover - you put the 4 small screws in LAST.

I have the same cracks on my p2v+ v 1

Over 150 plus flights I attribute it to over tightening screws. I used JB weld and crazy clue for now. I have an extra body on stand by...I have no plans on opening my p3, God forbid if cracks start to show on it...

Over 150 plus flights I attribute it to over tightening screws. I used JB weld and crazy clue for now. I have an extra body on stand by...I have no plans on opening my p3, God forbid if cracks start to show on it...

Always tighten those four little screws last. By tightening I mean with a little precision screwdriver and snug. When super gluing, spread the crack to expose the surfaces for gluing and put glue in from inside and out. For finishing, after glue dries, sand it down using your wife or girlfriend's best 4 sided nail file on the finer sides without so much grit.

I have always backed off those 4 screws and re tighten them by hand when my plane is at my operating temperatures. I tighten an until I feal a light torque to them. I think that they are installed by torque value in a cooler environment and then when subject to warm area the plastic expands some and bingo to tight.... Stress crack.

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 1

- Views

- 3K

- Replies

- 1

- Views

- 2K

- Replies

- 1

- Views

- 975

D