followed the steps - nothing showing up on my mac laptopuse the DJI Go app and under MC settings tap on advanced settings.. then tap on " enter flight data mode " you will see the files on the quad then.... copy paste..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crashed today...

- Thread starter SteveVaus

- Start date

have done each of those steps - no joy - thanks for trying to help!sorry... I'm not a mac guy... first thing comes to mind... quad turned on... plug usb cable in then out and in again to see if the computer see's the quad... confirm with RC that the quad is in data mode...

have done each of those steps - no joy - thanks for trying to help!

See if this helps you to get them.

Flight Data Log Viewer DJI Phantom 3 and Inspire 1

Have done all that - tried several times - nothing ever show up on my computer. Will try again in the morning with fresh brain - thanks for trying to help... and sorry for the dinner delay earlier. I appreciate you.

- Joined

- Jan 13, 2016

- Messages

- 891

- Reaction score

- 356

I'm a carpenter and thusly have a good feel with my hands. The amount to tighten the props seems to be very logical to me but I understand that isn't the case with everyone. I think they should offer a torque specification so at least there is something documented for people to make use of if they wish.

Jiggy - The stiffness of plastics is very low compared to the stiffness of metals. The shear stress in a plastic hub to metal shaft, means the deformation of the metal shaft will be negligible if a plastic hub is mounted improperly or forcefully on a metal shaft. This makes provision for an effective torque spec difficult - there is a complex formula to determine this but in an application such as this just wouldn't be feasible.

When the plastic hub is mounted on to the metal shaft/thread - the axial load and best fit/location is actually achieved over the first 50% of the thread length/depth. The extra thread remaining is for locking/fixing the hub to the shaft. Nominal force (while holding the motor frame with one hand) on the prop hub is all that should be needed to secure the prop after initial hand spinning on to the shaft - the rotational force during flight in the direction of thread lock is plenty to keep it secure.

For the most part failure of any self tightening rotating element is that of the operator, poor maintenance or assembly of same. Usually lack of proper inspection of both male and female threads, the hub (for any cracking or foreign material buildup), constant over tightening during assembly, stripped/stretched threads, use of any thread locking material on plastic threads or on metal shafts with plastic hubs (Loctite) or addition of any kind of Teflon tape that can cause misalignment of mating threads.

It is called a lack of maintenance that is required to maintain proper condition for proper fit. Props are the number one part that gives you flight - it is imperative then, that all pre flight checks include prop and shaft inspection each and every time prior to installation and take off.

A properly fitted and secured and self tightening prop should not, on its own fly off the motor shaft during normal flight. Excluding poor maintenance of the prop hubs/threads and motor shaft threads, other reasons for props to fly off while in "normal" flight mode include, hitting obstructions, motor seized up, obstructed prop from something airborne or from the quad itself and/or anything else you can think that might get in the way of prop rotation.

appreciate the thoughtful input. this bird did not suffer from insufficient or improper maintenance. Not that many flights since new several weeks ago. Always carefully inspected and pre-flighted. I am **** like that before and after flights - whether flying quads, RC, or real aircraft (single and multi-engine rated with significant hours) Thanks again for the input.Jiggy - The stiffness of plastics is very low compared to the stiffness of metals. The shear stress in a plastic hub to metal shaft, means the deformation of the metal shaft will be negligible if a plastic hub is mounted improperly or forcefully on a metal shaft. This makes provision for an effective torque spec difficult - there is a complex formula to determine this but in an application such as this just wouldn't be feasible.

When the plastic hub is mounted on to the metal shaft/thread - the axial load and best fit/location is actually achieved over the first 50% of the thread length/depth. The extra thread remaining is for locking/fixing the hub to the shaft. Nominal force (while holding the motor frame with one hand) on the prop hub is all that should be needed to secure the prop after initial hand spinning on to the shaft - the rotational force during flight in the direction of thread lock is plenty to keep it secure.

For the most part failure of any self tightening rotating element is that of the operator, poor maintenance or assembly of same. Usually lack of proper inspection of both male and female threads, the hub (for any cracking or foreign material buildup), constant over tightening during assembly, stripped/stretched threads, use of any thread locking material on plastic threads or on metal shafts with plastic hubs (Loctite) or addition of any kind of Teflon tape that can cause misalignment of mating threads.

It is called a lack of maintenance that is required to maintain proper condition for proper fit. Props are the number one part that gives you flight - it is imperative then, that all pre flight checks include prop and shaft inspection each and every time prior to installation and take off.

A properly fitted and secured and self tightening prop should not, on its own fly off the motor shaft during normal flight. Excluding poor maintenance of the prop hubs/threads and motor shaft threads, other reasons for props to fly off while in "normal" flight mode include, hitting obstructions, motor seized up, obstructed prop from something airborne or from the quad itself and/or anything else you can think that might get in the way of prop rotation.

Well I cannot attribute mine to improper maintenance either. Also since the crash I have used the same props with no adverse effects. The only thing that stands out in your post (for my experience) in "seized motor", but I will never know as DJI never told me what the problem was. I didn't hit anything and I had clear vision as it was only at a height of 20m. It was repaired under warranty though. So for me it was either seized motor or incorrect tightening of props by me onto the hub.Jiggy - The stiffness of plastics is very low compared to the stiffness of metals. The shear stress in a plastic hub to metal shaft, means the deformation of the metal shaft will be negligible if a plastic hub is mounted improperly or forcefully on a metal shaft. This makes provision for an effective torque spec difficult - there is a complex formula to determine this but in an application such as this just wouldn't be feasible.

When the plastic hub is mounted on to the metal shaft/thread - the axial load and best fit/location is actually achieved over the first 50% of the thread length/depth. The extra thread remaining is for locking/fixing the hub to the shaft. Nominal force (while holding the motor frame with one hand) on the prop hub is all that should be needed to secure the prop after initial hand spinning on to the shaft - the rotational force during flight in the direction of thread lock is plenty to keep it secure.

For the most part failure of any self tightening rotating element is that of the operator, poor maintenance or assembly of same. Usually lack of proper inspection of both male and female threads, the hub (for any cracking or foreign material buildup), constant over tightening during assembly, stripped/stretched threads, use of any thread locking material on plastic threads or on metal shafts with plastic hubs (Loctite) or addition of any kind of Teflon tape that can cause misalignment of mating threads.

It is called a lack of maintenance that is required to maintain proper condition for proper fit. Props are the number one part that gives you flight - it is imperative then, that all pre flight checks include prop and shaft inspection each and every time prior to installation and take off.

A properly fitted and secured and self tightening prop should not, on its own fly off the motor shaft during normal flight. Excluding poor maintenance of the prop hubs/threads and motor shaft threads, other reasons for props to fly off while in "normal" flight mode include, hitting obstructions, motor seized up, obstructed prop from something airborne or from the quad itself and/or anything else you can think that might get in the way of prop rotation.

Mark The Droner

Premium Pilot

- Joined

- Aug 26, 2015

- Messages

- 5,400

- Reaction score

- 1,821

I think the phrase should be omitted altogether. It made perfect sense in the P2 days and was encouraged by DJI themselves, but it doesn't apply to the P3 at all.Well Marko - "self tightening" is a bit of a mis-leading phrase when taken literally. ....

Hi SteveVaus,

Using an iMac, here are the steps to access the .DAT files stored on the hidden SD card permanently mounted inside the Phantom 3.

Also see the attached photos for a clearer viewpoint.

These first four steps below are from the "Drones Made Easy" website… support.dronesmadeeasy.com/hc/en-us/articles/206171443

1. Power up everything with the Phantom 3 as if you were going to fly (except the props), and launch the DJI GO App.

Enter the camera view.

2. In the MC Settings menu, choose Advanced Settings. You can find the MC Settings on the top leftcorner of the screen,

directly to the right of the Home icon.

3. Scroll down, and select Enter flight data mode.

4. The DJI GO app will prompt you to connect the drone to a PC or Mac via the USB to mini-USB cable included with your drone package.

The mini-USB port on the Phantom 3 is located on the front or nose of the drone, (and not the camera gimbal frame).

Plug the regular USB plug directly into your Mac (not a USB extension port box).

Note: This was done using a 2013 iMac running OSX 10.8.5, there may be some differences with different models and OSX versions.

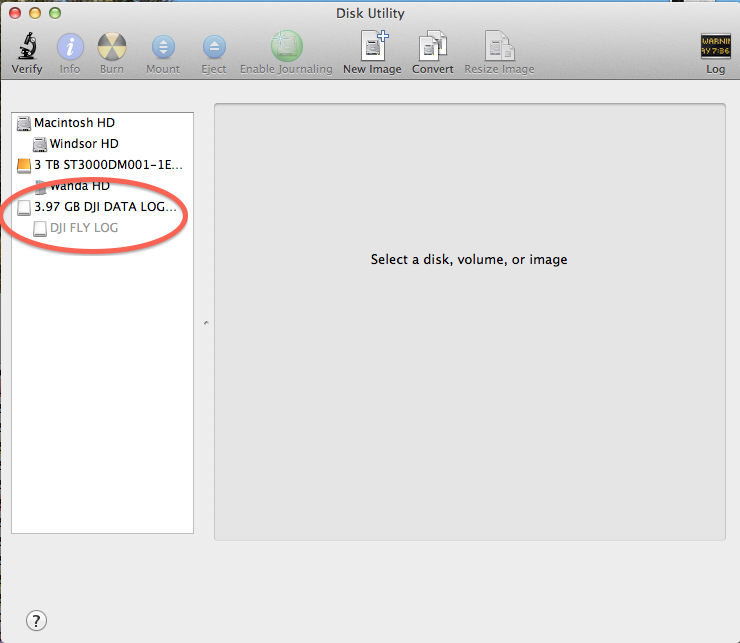

5. Once you connect the drone to your computer wait to see if by chance it does mount to your desktop.

When it doesn't, open the application Disk Utility.

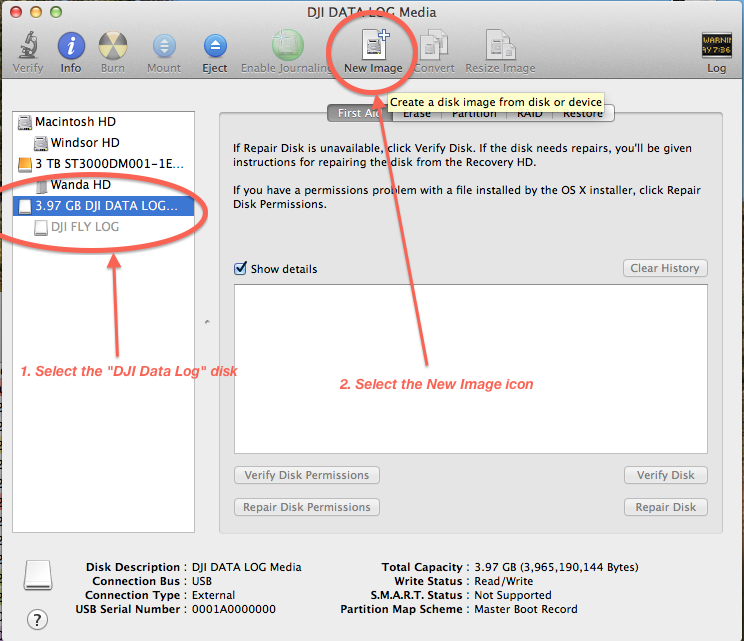

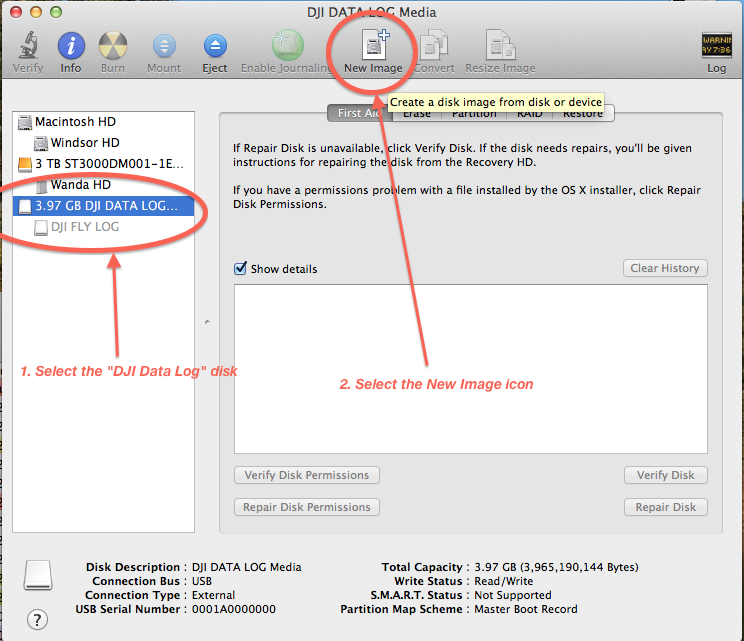

6. Select the disk DJI DATA LOG. It will show listed in the left column of disks in Disk Utility.

You can select it even though it is not mounted to the desktop.

(Be sure to choose the root disk DJI DATA LOG file and not the DJI FLY LOG file).

7. When the disk DJI DATA LOG is highlighted, select the New Image icon in the top row.

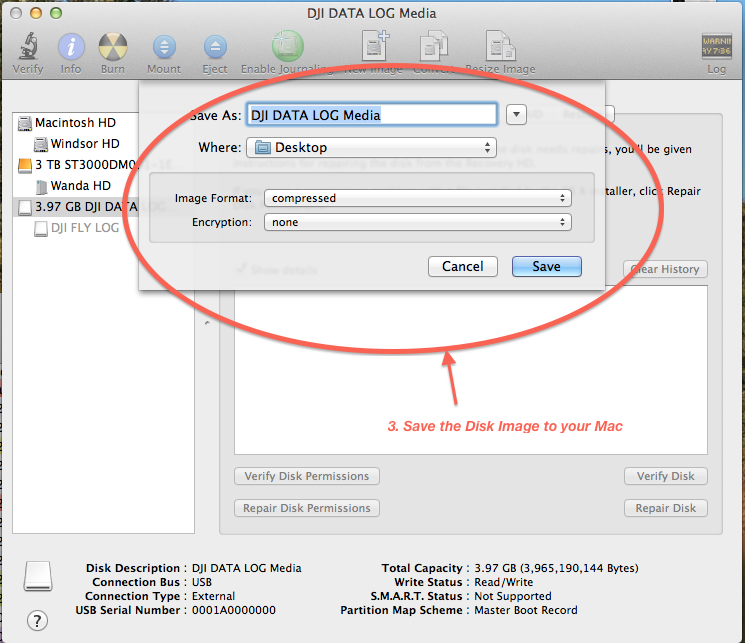

This will present the dialog box shown, asking what to name it, where to save it and what format.

(I've chosen compressed with no encryption).

8. Be prepared to wait along time… The amount of time depends on how many .DAT files there are.

The entire SD card could be full. The Phantom records a .DAT file every time it is powered on,

regardless of flight or not. It only erases them when space is needed for newer files.

(I wouldn't start with the Phantom battery less than 50% charged).

9. Once the Disk Image is created on your Mac, double-click it, it will uncompress to a new window

(in temporary RAM memory only). Drag the files you want from there to a newly created folder on your computer.

That's it!

10. The FLYxx.DAT files will have considerably more recorded flight information than the

DJIFlightRecord text files that are copied from the DJI GO app.

The FLYxx.DAT files can now be analyzed for content, but how to do that is a whole different topic…

Using an iMac, here are the steps to access the .DAT files stored on the hidden SD card permanently mounted inside the Phantom 3.

Also see the attached photos for a clearer viewpoint.

These first four steps below are from the "Drones Made Easy" website… support.dronesmadeeasy.com/hc/en-us/articles/206171443

1. Power up everything with the Phantom 3 as if you were going to fly (except the props), and launch the DJI GO App.

Enter the camera view.

2. In the MC Settings menu, choose Advanced Settings. You can find the MC Settings on the top leftcorner of the screen,

directly to the right of the Home icon.

3. Scroll down, and select Enter flight data mode.

4. The DJI GO app will prompt you to connect the drone to a PC or Mac via the USB to mini-USB cable included with your drone package.

The mini-USB port on the Phantom 3 is located on the front or nose of the drone, (and not the camera gimbal frame).

Plug the regular USB plug directly into your Mac (not a USB extension port box).

Note: This was done using a 2013 iMac running OSX 10.8.5, there may be some differences with different models and OSX versions.

5. Once you connect the drone to your computer wait to see if by chance it does mount to your desktop.

When it doesn't, open the application Disk Utility.

6. Select the disk DJI DATA LOG. It will show listed in the left column of disks in Disk Utility.

You can select it even though it is not mounted to the desktop.

(Be sure to choose the root disk DJI DATA LOG file and not the DJI FLY LOG file).

7. When the disk DJI DATA LOG is highlighted, select the New Image icon in the top row.

This will present the dialog box shown, asking what to name it, where to save it and what format.

(I've chosen compressed with no encryption).

8. Be prepared to wait along time… The amount of time depends on how many .DAT files there are.

The entire SD card could be full. The Phantom records a .DAT file every time it is powered on,

regardless of flight or not. It only erases them when space is needed for newer files.

(I wouldn't start with the Phantom battery less than 50% charged).

9. Once the Disk Image is created on your Mac, double-click it, it will uncompress to a new window

(in temporary RAM memory only). Drag the files you want from there to a newly created folder on your computer.

That's it!

10. The FLYxx.DAT files will have considerably more recorded flight information than the

DJIFlightRecord text files that are copied from the DJI GO app.

The FLYxx.DAT files can now be analyzed for content, but how to do that is a whole different topic…

- Joined

- Sep 17, 2015

- Messages

- 240

- Reaction score

- 87

- Age

- 55

I do the same thing. WITHOUT the wrench or other assistance, I grab the motor hub, and without even going out nearly to the end of the prop for mechanical advantage, I tighten it hard. Which because I'm restraining the motor hub with two fingers, and I'm not twisting far out on the prop, I'm not capable of causing thread damage.I spin them on then with my hands tighten as far as they'll go

I once very accidentally just spun the props down until they reached bottom, and didn't tighten them AT ALL. I actually made 5 minutes before red warning messages like ENGINE STRIKE, ENGINE AT IDLE popped up, and I could quickly set it down. The props WERE semi-snug (barely), the self tightening saved me. But trouble shooting, at idle, a monster resonant type vibration spontaneously started. Induced by a loose prop. Lucky me. Above is how I now tighten, and religiously pre-flight. I like the idea of some guidance like torque value -- something. But what I do makes them tight and won't damage threads.

- Joined

- Sep 17, 2015

- Messages

- 240

- Reaction score

- 87

- Age

- 55

Blade Chroma's were having this problem. They have a rubber washer under the prop, and the instructions said "hand snug", which is REALLY VAGUE. People who were hitting washer resistance, and then snugging them tighter just a little more were having lots of propeller losses. The solution in the forums was hand tighten (only) them down hard.

- Joined

- Sep 17, 2015

- Messages

- 240

- Reaction score

- 87

- Age

- 55

Wow, superbly informative and knowledgeable post. With all your criteria met, I think you can under "snug" the prop tightness if you just tighten a tad after resistance is felt. Although my near disaster occurred with no hand snugging at all.Jiggy - The stiffness of plastics is very low compared to the stiffness of metals. The shear stress in a plastic hub to metal shaft, means the deformation of the metal shaft will be negligible if a plastic hub is mounted improperly or forcefully on a metal shaft. This makes provision for an effective torque spec difficult - there is a complex formula to determine this but in an application such as this just wouldn't be feasible.

When the plastic hub is mounted on to the metal shaft/thread - the axial load and best fit/location is actually achieved over the first 50% of the thread length/depth. The extra thread remaining is for locking/fixing the hub to the shaft. Nominal force (while holding the motor frame with one hand) on the prop hub is all that should be needed to secure the prop after initial hand spinning on to the shaft - the rotational force during flight in the direction of thread lock is plenty to keep it secure.

For the most part failure of any self tightening rotating element is that of the operator, poor maintenance or assembly of same. Usually lack of proper inspection of both male and female threads, the hub (for any cracking or foreign material buildup), constant over tightening during assembly, stripped/stretched threads, use of any thread locking material on plastic threads or on metal shafts with plastic hubs (Loctite) or addition of any kind of Teflon tape that can cause misalignment of mating threads.

It is called a lack of maintenance that is required to maintain proper condition for proper fit. Props are the number one part that gives you flight - it is imperative then, that all pre flight checks include prop and shaft inspection each and every time prior to installation and take off.

A properly fitted and secured and self tightening prop should not, on its own fly off the motor shaft during normal flight. Excluding poor maintenance of the prop hubs/threads and motor shaft threads, other reasons for props to fly off while in "normal" flight mode include, hitting obstructions, motor seized up, obstructed prop from something airborne or from the quad itself and/or anything else you can think that might get in the way of prop rotation.

With just thumb and forefinger restraining the motor hub, with several finger on your other hand tightening the prop near the hub, and not trying to be a gorilla about it, I don't think you can apply nearly enough force to hurt the threads (I can't), but the prop will be tight. I also remove the props periodically, and look at the threads and everything to make sure everything looks perfect. ANY doubts, and I replace it. I've never had a thread issue, just little dings on the edges.

- Joined

- Sep 17, 2015

- Messages

- 240

- Reaction score

- 87

- Age

- 55

Eaglegoaltender -- You sure sound like a mechanical engineer, I'd practically bet money on it. So I imagine you'll have an opinion on this question (Anyone can chime in): In some applications, like helicopter rotors, the part is so critical that it has a specified service life, after which it's replacement is mandatory. This in spite of maintenance procedures that might include Maga Flux examination and other sophisticated methods.Jiggy - The stiffness of plastics is very low compared to the stiffness of metals. The shear stress in a plastic hub to metal shaft, means the deformation of the metal shaft will be negligible if a plastic hub is mounted improperly or forcefully on a metal shaft. This makes provision for an effective torque spec difficult - there is a complex formula to determine this but in an application such as this just wouldn't be feasible.

When the plastic hub is mounted on to the metal shaft/thread - the axial load and best fit/location is actually achieved over the first 50% of the thread length/depth. The extra thread remaining is for locking/fixing the hub to the shaft. Nominal force (while holding the motor frame with one hand) on the prop hub is all that should be needed to secure the prop after initial hand spinning on to the shaft - the rotational force during flight in the direction of thread lock is plenty to keep it secure.

For the most part failure of any self tightening rotating element is that of the operator, poor maintenance or assembly of same. Usually lack of proper inspection of both male and female threads, the hub (for any cracking or foreign material buildup), constant over tightening during assembly, stripped/stretched threads, use of any thread locking material on plastic threads or on metal shafts with plastic hubs (Loctite) or addition of any kind of Teflon tape that can cause misalignment of mating threads.

It is called a lack of maintenance that is required to maintain proper condition for proper fit. Props are the number one part that gives you flight - it is imperative then, that all pre flight checks include prop and shaft inspection each and every time prior to installation and take off.

A properly fitted and secured and self tightening prop should not, on its own fly off the motor shaft during normal flight. Excluding poor maintenance of the prop hubs/threads and motor shaft threads, other reasons for props to fly off while in "normal" flight mode include, hitting obstructions, motor seized up, obstructed prop from something airborne or from the quad itself and/or anything else you can think that might get in the way of prop rotation.

FINALLY (sorry): Would you see any need to replace a propeller that still looks fine, but has reached a certain age or number of flights? It seems like plastic is less likely to hide emerging defects like a metal helicopter blade could, but I'm only an electrical engineer, but have good common sense, but I know when I don't know something, and that's the case here. LOL. Also, even if not the props, anything else on a quad that should prudently be replaced on an age or use basis alone? THANKS

- Joined

- Sep 17, 2015

- Messages

- 240

- Reaction score

- 87

- Age

- 55

It's worth mentioning, that when I stupidly replaced my propellers, and only spun them down on the shafts, and 3 days later forgot to tighten them at ALL, now that I think about it my first BIG RED WARNING WAS: "Engine Seizure (or OBSTRUCTION)"!!, followed by "Engine at Idle". I said in another post that I was baffled, because everything looked fine afterwards. But later, idling on my coffee table, an exponentially growing vibration started, right out of the blue! I grabbed a landing skid, and it stopped. THEN I remember my non tightening idiotic mistake, but I did find the props "a very little snug". But I could loosen then by hand VERY easily. I think a loose prop caused a violent resonance amplified vibration to start that got so violent that something caused the motor to bind. When I flipped out, and changed my throttle setting, I bet I damped the vibration out, and then landing quick enough to avoid any further weirdness.According to your healthy drones report, there was a motor obstruction warning recorded. This might indicate your motor seized, and the propeller spun off as a result. This could mean, even if the propellers were wrenched on, a crash would have occurred due to the motor fail and the lost prop is a symptom. Looks like DJI will hook you up, if it proves to be a motor fail.

Did it get a ton of sand in it before launch? Any clue why the motor might have seized?

So here, "Engine Seizure/OBSTRUCTION" was caused by a very atypical phenomenon, and not the usual suspects. And something to do with loose props was the prime suspect. I've never seen it since, but I never will fly without checking prop tightness again. Jeez.

- Joined

- Jan 13, 2016

- Messages

- 891

- Reaction score

- 356

I don't think you can apply nearly enough force to hurt the threads

Thank you Phantom1972 - you are correct with that statement, to a point - there is a "fail safe" (if I can use that phrase in this context) where the "shoulder" of the prop hub meets the top of the motor housing before the prop hub "bottoms out" on the metal shaft thread.

No doubt they thought of that when engineering the prop fit so people wouldn't be stripping the threads with regularity - once the prop hub shoulder meets with the motor frame it would be difficult to turn more to a point where you would strip the hub threads (unless as you put it, someone used "Gorilla" force) without compressing that shoulder significantly at which point (very excessive force) you could stretch the threads.

I haven't as yet used a depth gauge to measure from that hub shoulder to the bottom of the hub housing depth - however I plan on doing that and comparing it to the length of the metal shaft (from tip of shaft to motor frame top). Just to confirm there is no bottoming out at the hub onto the metal shaft (doubtful there is due to that shoulder hitting first).

I did place a bit of regular blank notebook paper on top of the motor frame where the prop hub shoulder fits - then I spun on the prop till it stopped and the paper was locked in there - so that does tell us the shoulder is hitting/fitting/seating as designed and not prior to bottoming out on the threads. If you look closely under the prop after "spinning" the prop on - you can see where the hub shoulder meets the motor top frame - so that little extra snug tightening is very limited and really just seats the hub to the motor frame top. If there was no shoulder there - the "prop self tightening" process would end up ripping the threads while in flight!

Have done all that - tried several times - nothing ever show up on my computer. Will try again in the morning with fresh brain - thanks for trying to help... and sorry for the dinner delay earlier. I appreciate you.

Steve, sounds like you're almost there. Normally when the pc and P3 are enabled to communicate in the GO app, a box should pop up asking what you want to. You select view files or images and it opens up to the .DAT files. You then select the flight in question and save it to a folder on your pc.

BUT...since the box is not popping up, at this point on your pc go Start/Computer. You should then see some kind of reference to your P3. Double click and you should see the files.

This is not as hard as it may appear so do not get discouraged.

- Joined

- Jan 13, 2016

- Messages

- 891

- Reaction score

- 356

But later, idling on my coffee table, an exponentially growing vibration started, right out of the blue! I grabbed a landing skid, and it stopped.

No doubt there as to a growing vibration or sudden feel of same - with the props not turning at "exactly" the same rpm even while idling - there is a phenom known as a "beat frequency" that creates an addition and subtraction of vibration amplitudes.

This is the result of two closely spaced frequencies (rpm) that have near or same amplitude of vibration that are going in and out of phase with each other.

When the peaks coincide (in-phase), they add together (addition) and increase more vibration than the single signal produces alone.

When they oppose one another (out-of-phase), they cancel each other out (subtraction) and the vibration disappears for a time determined by the differences or spacing of the frequencies of concern (amount of rpm differences).

I think a loose prop caused a violent resonance amplified vibration

Good call when you mention "resonance" - whenever a forcing frequency (prop rpm) meets with a natural frequency (Phantom structure) the resulting force is called "resonance".

This activity can be very excessive and increase nominal vibration amplitude up to 100x the value. No doubt the natural frequency of the Phantom has been well tested at DJI in order to have the variable motor/prop rpm not interfere with the Phantom's structure - so as to avoid a resonant condition.

However, when there is a change to one of either the tested and accepted rpm (forcing frequency) or the structure of the Phantom's (natural frequency) - the natural frequency and forcing frequencies also change and can result in a serious resonant condition while in flight (even your suspected loose prop while in flight could do that).

EDIT:

I grabbed a landing skid, and it stopped.

This is what I was explaining with regard to resonance - when you grabbed a landing skid - you added "stiffness" to the Phantom's structure - hence you removed that natural frequency away from the offending forcing frequency.

Stiffening increases a natural frequency where damping will lower it.

Last edited:

- Joined

- Jan 13, 2016

- Messages

- 891

- Reaction score

- 356

Sorry I missed that post from you.....

`

LOL - well let's see, how much money do you want to bet on that?

When taking these plastic Phantom props into consideration with your question - The biggest fear I have and IMO the issues with props that have been in service for some time and are flying off is my concern with regard to the stress and/or strain strength curve for plastics since they are very temperature dependent.

The Phantom motors get very hot while in service and obviously plastic expands at a much faster rate than the metal shaft (threads) would when they are experiencing the same thermal load/temperatures. On going thermal expansion and contraction at the Prop hub should be a concern over time.

Any fastener - has what is called a "clamp load" and usually this is not a concern if both the male and female connectors are made of the same material. However, since the Phantom prop hubs/thread is plastic and the shaft is metal, the thermal expansion rate is not equal and in fact the plastic threads will expand faster and further than that of the metal shaft/thread resulting in a poor fit.

That makes me wonder if someone is experience a hotter than usual or accepted motor temperature due to issues with that motor, if the prop plastic hub/threads expansion rate doesn't happen much quicker and with more consequential results - prop, fly offs. Keep in mind here that all plastic fasteners when exposed to a thermal load will 'creep" due to expansion and again in particular when the plastic fastener is mounted on a metal shaft/thread where both are exposed to thermal load and who's expansion rate is very different to one another.

The "creep rate" while under thermal load and more importantly for us having the prop hubs exposed to what we have here as to unequal thermal expansion rate - will have a negative effect on securing the hardware to where its intended purpose lies. Creeping will most definitely create a loss with "clamp load"! One might argue that since the props are "self tightening" the loss of clamping is negligible - however I would say one must keep in mind that loss of clamping from creeping is also a product of over loading - and since these are "self tightening" the load is constant load while rotating.

As mentioned above, and something to keep in mind with these props and hub fasteners----when exposed to high load or thermal activity, all plastics will creep.

One method often applied to reducing the creep factor and maintain the clamp load is to lesson the load when installing this type of fastener (plastic) by not over tightening - however for us and as mentioned above but worth repeating - with our Phantoms since these are considered "self tightening" that method basically goes out the window since on start-up there is added load which is constant and on going load during flight!

`

You sure sound like a mechanical engineer, I'd practically bet money on it.

LOL - well let's see, how much money do you want to bet on that?

Would you see any need to replace a propeller that still looks fine, but has reached a certain age or number of flights? It seems like plastic is less likely to hide emerging defects like a metal helicopter blade could,

When taking these plastic Phantom props into consideration with your question - The biggest fear I have and IMO the issues with props that have been in service for some time and are flying off is my concern with regard to the stress and/or strain strength curve for plastics since they are very temperature dependent.

The Phantom motors get very hot while in service and obviously plastic expands at a much faster rate than the metal shaft (threads) would when they are experiencing the same thermal load/temperatures. On going thermal expansion and contraction at the Prop hub should be a concern over time.

Any fastener - has what is called a "clamp load" and usually this is not a concern if both the male and female connectors are made of the same material. However, since the Phantom prop hubs/thread is plastic and the shaft is metal, the thermal expansion rate is not equal and in fact the plastic threads will expand faster and further than that of the metal shaft/thread resulting in a poor fit.

That makes me wonder if someone is experience a hotter than usual or accepted motor temperature due to issues with that motor, if the prop plastic hub/threads expansion rate doesn't happen much quicker and with more consequential results - prop, fly offs. Keep in mind here that all plastic fasteners when exposed to a thermal load will 'creep" due to expansion and again in particular when the plastic fastener is mounted on a metal shaft/thread where both are exposed to thermal load and who's expansion rate is very different to one another.

The "creep rate" while under thermal load and more importantly for us having the prop hubs exposed to what we have here as to unequal thermal expansion rate - will have a negative effect on securing the hardware to where its intended purpose lies. Creeping will most definitely create a loss with "clamp load"! One might argue that since the props are "self tightening" the loss of clamping is negligible - however I would say one must keep in mind that loss of clamping from creeping is also a product of over loading - and since these are "self tightening" the load is constant load while rotating.

As mentioned above, and something to keep in mind with these props and hub fasteners----when exposed to high load or thermal activity, all plastics will creep.

One method often applied to reducing the creep factor and maintain the clamp load is to lesson the load when installing this type of fastener (plastic) by not over tightening - however for us and as mentioned above but worth repeating - with our Phantoms since these are considered "self tightening" that method basically goes out the window since on start-up there is added load which is constant and on going load during flight!

These directions were VERY helpful. Slightly different in Disk Image v15 but it is downloading now.Hi SteveVaus,

Using an iMac, here are the steps to access the .DAT files stored on the hidden SD card permanently mounted inside the Phantom 3.

Also see the attached photos for a clearer viewpoint.

These first four steps below are from the "Drones Made Easy" website… support.dronesmadeeasy.com/hc/en-us/articles/206171443

1. Power up everything with the Phantom 3 as if you were going to fly (except the props), and launch the DJI GO App.

Enter the camera view.

2. In the MC Settings menu, choose Advanced Settings. You can find the MC Settings on the top leftcorner of the screen,

directly to the right of the Home icon.

3. Scroll down, and select Enter flight data mode.

4. The DJI GO app will prompt you to connect the drone to a PC or Mac via the USB to mini-USB cable included with your drone package.

The mini-USB port on the Phantom 3 is located on the front or nose of the drone, (and not the camera gimbal frame).

Plug the regular USB plug directly into your Mac (not a USB extension port box).

Note: This was done using a 2013 iMac running OSX 10.8.5, there may be some differences with different models and OSX versions.

5. Once you connect the drone to your computer wait to see if by chance it does mount to your desktop.

When it doesn't, open the application Disk Utility.

6. Select the disk DJI DATA LOG. It will show listed in the left column of disks in Disk Utility.

You can select it even though it is not mounted to the desktop.

(Be sure to choose the root disk DJI DATA LOG file and not the DJI FLY LOG file).

7. When the disk DJI DATA LOG is highlighted, select the New Image icon in the top row.

This will present the dialog box shown, asking what to name it, where to save it and what format.

(I've chosen compressed with no encryption).

8. Be prepared to wait along time… The amount of time depends on how many .DAT files there are.

The entire SD card could be full. The Phantom records a .DAT file every time it is powered on,

regardless of flight or not. It only erases them when space is needed for newer files.

(I wouldn't start with the Phantom battery less than 50% charged).

9. Once the Disk Image is created on your Mac, double-click it, it will uncompress to a new window

(in temporary RAM memory only). Drag the files you want from there to a newly created folder on your computer.

That's it!

10. The FLYxx.DAT files will have considerably more recorded flight information than the

DJIFlightRecord text files that are copied from the DJI GO app.

The FLYxx.DAT files can now be analyzed for content, but how to do that is a whole different topic…

View attachment 44167 View attachment 44168 View attachment 44169 View attachment 44170

Similar threads

- Replies

- 25

- Views

- 3K

- Replies

- 1

- Views

- 842

- Replies

- 1

- Views

- 805

- Replies

- 1

- Views

- 929