- Joined

- Dec 11, 2018

- Messages

- 6

- Reaction score

- 0

- Age

- 49

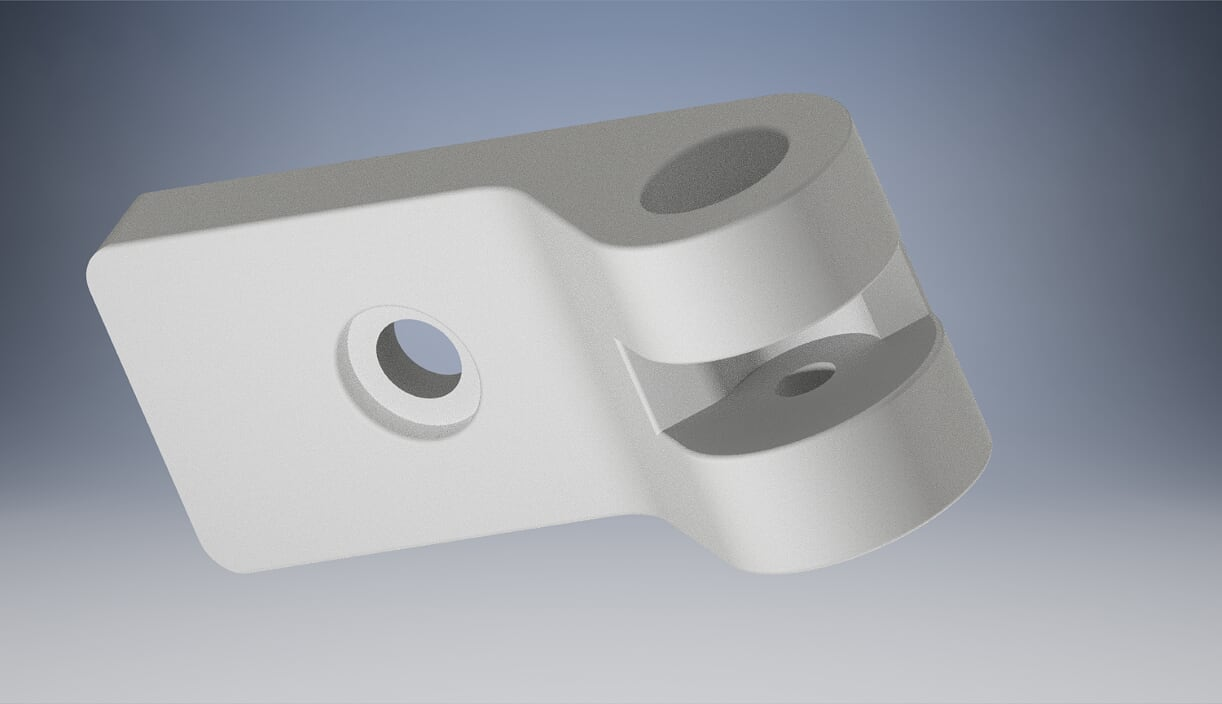

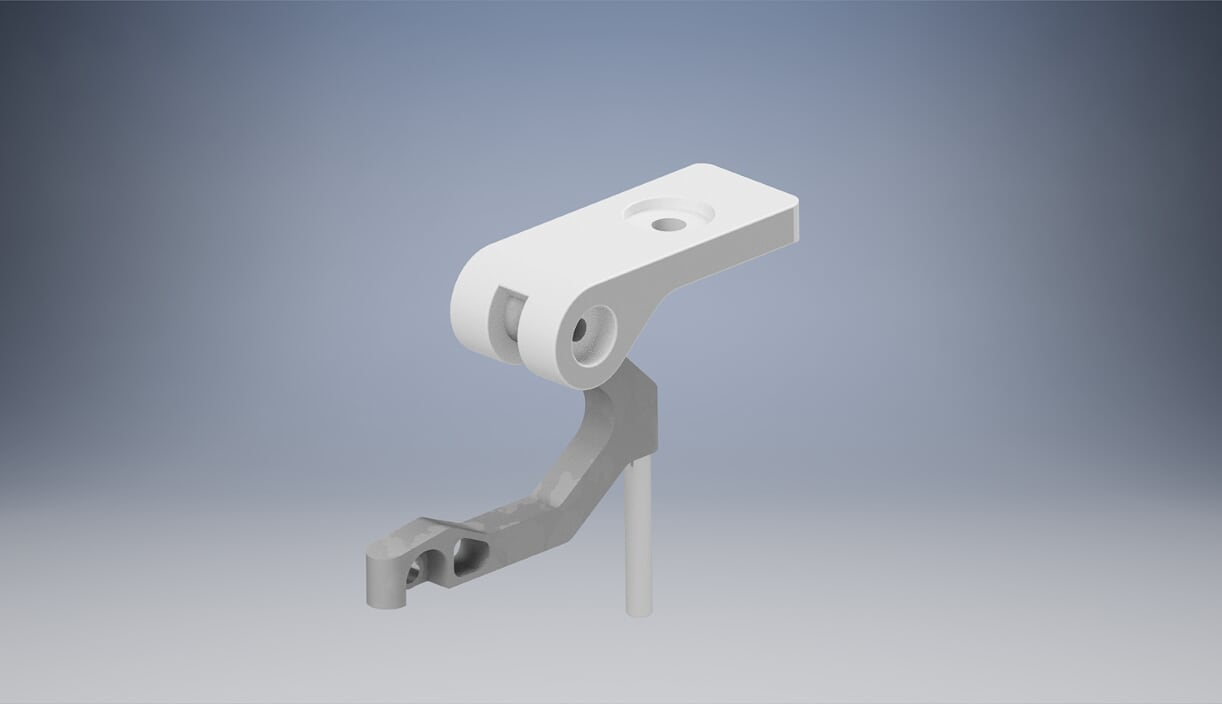

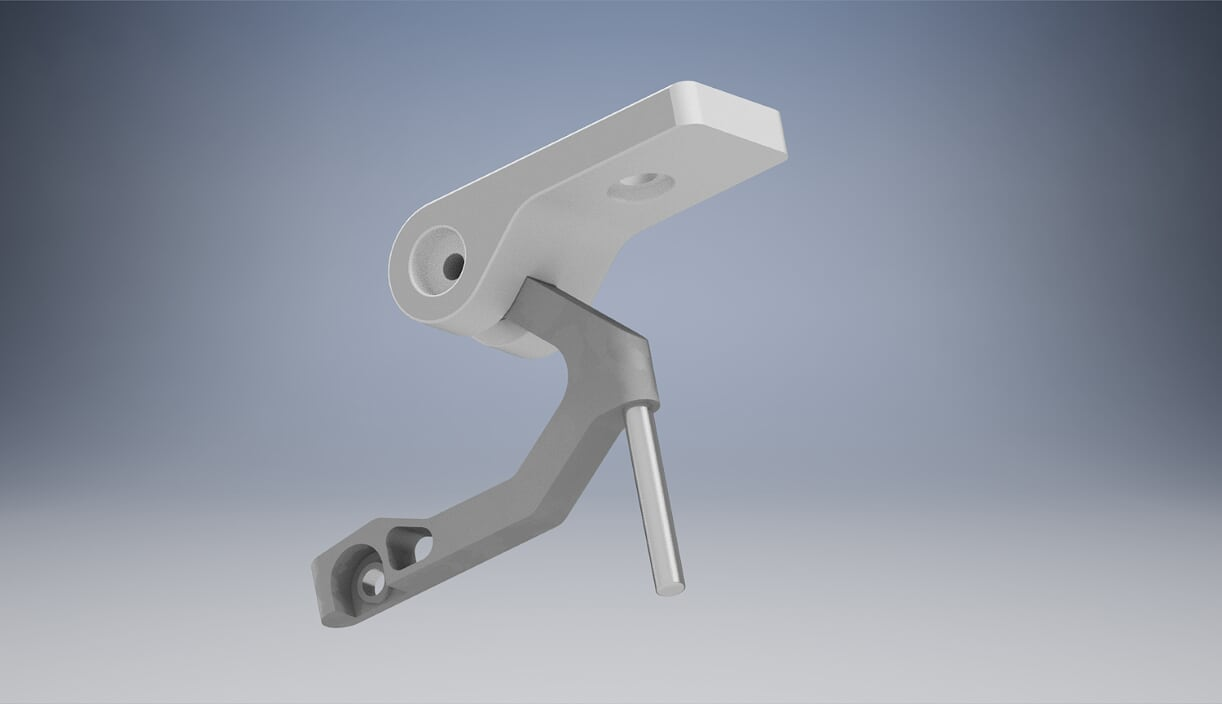

That's cool. Here is another option. I didn't model the ball but it would ideally be used with the rubber Ram Mount ball with female threaded fitting. The advantage this one has is that the weight and forces of the display are spread over the two original mounting points. The disadvantage is that it puts the whole assembly up higher. If I was doing this for myself, i'd just screw a ball into the top hole, like you are doing. If I was designing something for commercial sale, I would lean toward something like this.