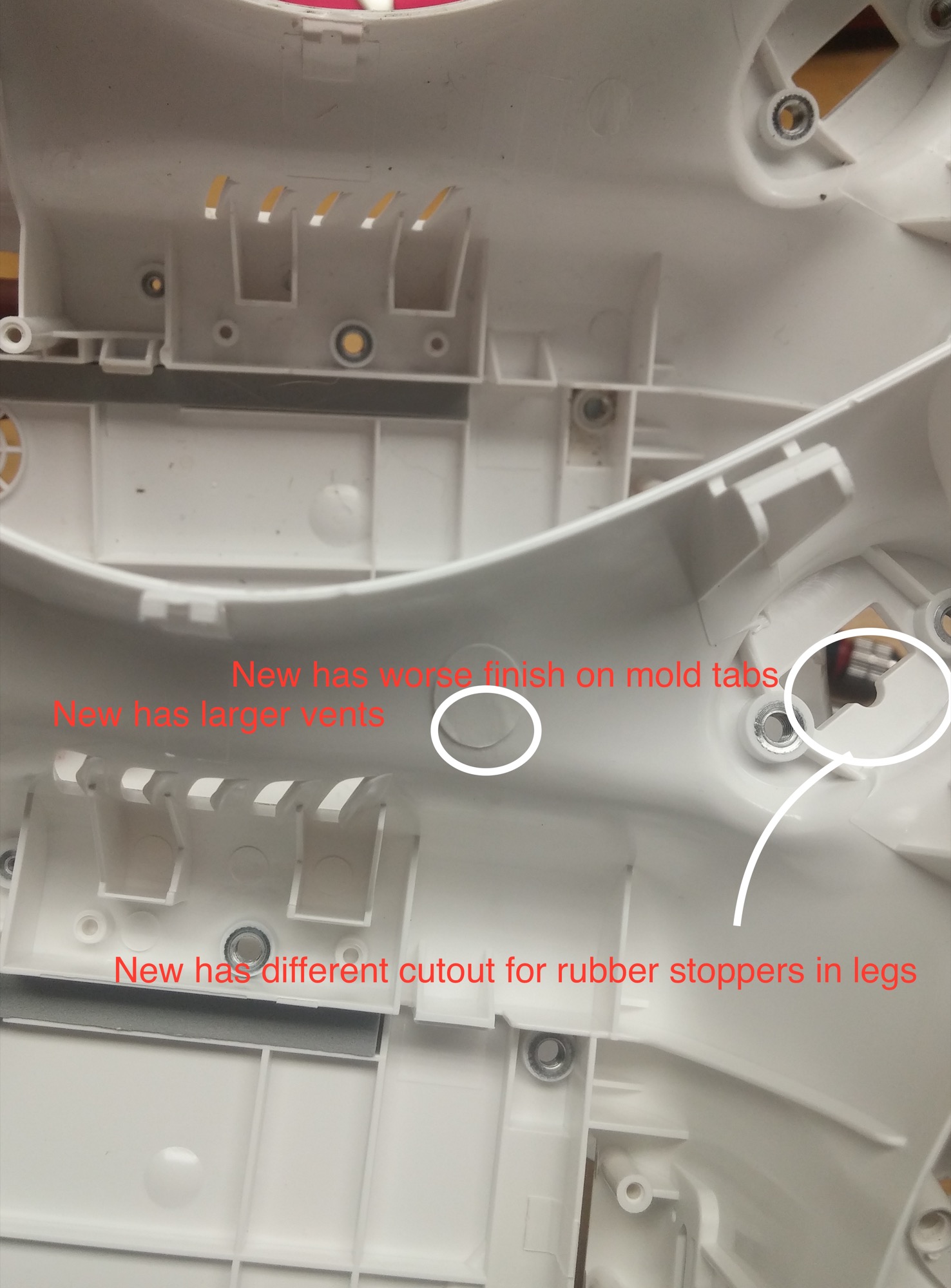

I took some pictures of the 2 different shells I have seen for P3A and P3P

Attachments

-

2015-10-04 15.47.14.jpg1 MB · Views: 1,864

2015-10-04 15.47.14.jpg1 MB · Views: 1,864 -

2015-10-04 15.47.24.jpg1.2 MB · Views: 1,705

2015-10-04 15.47.24.jpg1.2 MB · Views: 1,705 -

2015-10-04 15.49.10.jpg1.1 MB · Views: 1,771

2015-10-04 15.49.10.jpg1.1 MB · Views: 1,771 -

2015-10-04 15.48.09.jpg861.6 KB · Views: 1,686

2015-10-04 15.48.09.jpg861.6 KB · Views: 1,686 -

2015-10-04 15.46.44.jpg650.5 KB · Views: 1,665

2015-10-04 15.46.44.jpg650.5 KB · Views: 1,665 -

2015-10-04 15.46.11.jpg2.6 MB · Views: 1,734

2015-10-04 15.46.11.jpg2.6 MB · Views: 1,734 -

2015-10-04 15.45.34.jpg1.5 MB · Views: 1,719

2015-10-04 15.45.34.jpg1.5 MB · Views: 1,719