PhantomWetSuits

Approved Vendor

- Joined

- Jun 3, 2017

- Messages

- 1,338

- Reaction score

- 846

- Age

- 60

We have tested the drone in 100 degree heat in Tennessee , the day the of the totality and only experienced a 5 degree temp increase after several flights.

We have tested it for 26 minutes and than another 20 minutes in a torrential downpour and temps are not an issue of any kind as we have not blocked the vents but used bi level system that we developed to alow the water to cascade over the top of the drone as compared to letting the water slide down the drone, this is why we did not cover the entire drone as that would not have provided a bi level system.

So the Wetsuit allows the drone to negotiate water in a way that does not allow water to get in the drone, this was are goal and to do it in the most clever way we could.

The Wet Suit uses a 3m adhesive glue that cleans up beautifully with some goo gone , as far as the vent go they are not covered , what we have done is create a bi level allowing any rain to cascade over the top of it so no temperature change, and of course we have done tests showing that the 3 part system we developed to negotiate water is only now weighing 3.5 oz which has been exceptional.

As to the ability of the drone to float , we created a Surge Ring for the bottom of the unit where most of the water intake takes place and that has greatly increased the time the drone can stay in the water .

Because the Wet Suit for the Phantom 4 not only protects the Drone from Torrential Rain and Snow it also provides impact protection to the drone.

We have sold hundreds already and several news teams have come back and ordered more than one. its a thrilling new product for the Phantom 4 Series that only enhances everything the DJI already did to make it an all weather drone.

We think by having an all weather drone it puts the Phantom 4 back on top of the food chain over any other drone.

[

BEING LOGICAL IS NOT THE SAME AS BEING SMART ! Knowing more . The data is not missing, it just never been an issue.

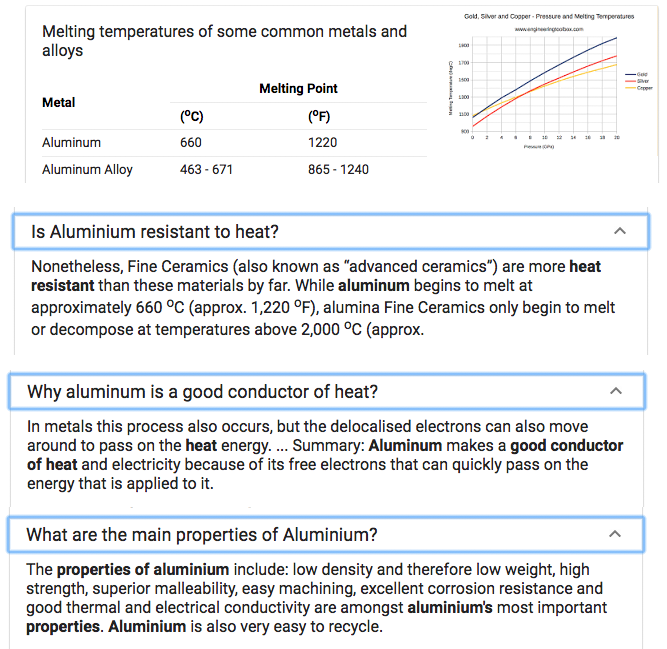

There is a reason whey DJI and APPLE use aluminum to withstand constant heat. The back of my Thunderbolt displays runs 110 degrees all day long for close to 3 years now with out ever being shut off.

The DJI Motors ran at about 96 to 105 degrees for 30 minutes, If we run them 3 times exchanging batteries we get the same temps. If we run them 4 times in a row we can sometimes if its 100 degrees outside get them to 120 degrees which is nothing .

Bottom line they are designed to run incredibly hot without issues of any kind and that is why DJI chose that material to house the motors in..

If we go to the extreme and take the PROPS while we run the engines we get the same 96 to 105 degrees which we could run all day long.

For those wondering if we close off the vents , we do not, the vents are not closed off, we just made it much more difficult for the water to get in.

Below is some information as to why DJI AND APPLE use this amazing material to negotiate heat.

LONG LIVE DJI ALUMINUM MOTORS AND THERE AMAZING ABILITY TO NEGOTIATE INCREDIBLE HEAT TEMPS:

We have tested it for 26 minutes and than another 20 minutes in a torrential downpour and temps are not an issue of any kind as we have not blocked the vents but used bi level system that we developed to alow the water to cascade over the top of the drone as compared to letting the water slide down the drone, this is why we did not cover the entire drone as that would not have provided a bi level system.

So the Wetsuit allows the drone to negotiate water in a way that does not allow water to get in the drone, this was are goal and to do it in the most clever way we could.

The Wet Suit uses a 3m adhesive glue that cleans up beautifully with some goo gone , as far as the vent go they are not covered , what we have done is create a bi level allowing any rain to cascade over the top of it so no temperature change, and of course we have done tests showing that the 3 part system we developed to negotiate water is only now weighing 3.5 oz which has been exceptional.

As to the ability of the drone to float , we created a Surge Ring for the bottom of the unit where most of the water intake takes place and that has greatly increased the time the drone can stay in the water .

Because the Wet Suit for the Phantom 4 not only protects the Drone from Torrential Rain and Snow it also provides impact protection to the drone.

We have sold hundreds already and several news teams have come back and ordered more than one. its a thrilling new product for the Phantom 4 Series that only enhances everything the DJI already did to make it an all weather drone.

We think by having an all weather drone it puts the Phantom 4 back on top of the food chain over any other drone.

[

BEING LOGICAL IS NOT THE SAME AS BEING SMART ! Knowing more . The data is not missing, it just never been an issue.

There is a reason whey DJI and APPLE use aluminum to withstand constant heat. The back of my Thunderbolt displays runs 110 degrees all day long for close to 3 years now with out ever being shut off.

The DJI Motors ran at about 96 to 105 degrees for 30 minutes, If we run them 3 times exchanging batteries we get the same temps. If we run them 4 times in a row we can sometimes if its 100 degrees outside get them to 120 degrees which is nothing .

Bottom line they are designed to run incredibly hot without issues of any kind and that is why DJI chose that material to house the motors in..

If we go to the extreme and take the PROPS while we run the engines we get the same 96 to 105 degrees which we could run all day long.

For those wondering if we close off the vents , we do not, the vents are not closed off, we just made it much more difficult for the water to get in.

Below is some information as to why DJI AND APPLE use this amazing material to negotiate heat.

LONG LIVE DJI ALUMINUM MOTORS AND THERE AMAZING ABILITY TO NEGOTIATE INCREDIBLE HEAT TEMPS:

Last edited: