- Joined

- Oct 15, 2017

- Messages

- 125

- Reaction score

- 44

- Age

- 47

I've peppered the forum with various questions on my Phantom 4 Advanced lower shell replacement, so I thought I'd chronicle my path through this project, as I did hit a few snags. Maybe somebody will find this useful...

So, the root of my problems was stress cracks that developed on both rear arms of my drone. The drone is about 2 1/2 years old, and has never crashed or really even had a hard landing, so the cause is a mystery. It's either the material used in the plastic getting stressed over time, or my drone backpack exerting pressure in the wrong places. I might put out a separate post on that to see what thoughts people have. At any rate, the cracks didn't affect the way the drone handled, but they made me uneasy. Upon getting the thing apart, I found the cracks extended not only through the shell, but also through a ridge surrounding the vent hole.

Shell Crack:

I ordered a new lower shell from Amazon for $35 - be aware that the P4A has a unique lower shell, since it lacks the side and rear vision sensors of the P4P, so you can't use a P4P lower shell on a P4A unless you want empty holes in the shell. The first snag in the project came early - my new shell arrived damaged. I ordered another and returned the damaged one, a process that set me back a couple of days.

New Lower Shell:

The guy who did the following YouTube video did all the hard work - this is not my video, but it details a complete shell replacement on a Phantom 4 Pro. It was pretty much my bible for the project:

Again, the video shows a complete shell replacement, a much more involved task than just replacing the lower shell like I needed. I got lucky that my cracks stayed on the lower shell; otherwise, the motors need to be unsoldered and resoldered, which is apparently a chore.

The basic disassembly went OK, but once all the screws are removed, the shell is really tough to get apart. The videos will tell you to press in around tabs located on the bottom shell, but this didn't work well for me, and in the end, brute force had to be applied. I broke one of the locating tabs on the old lower shell doing this, but since it was going to be replaced, this wasn't an issue.

Drone in Pieces:

There are metal brackets to contain the gimbal cable and the antenna wires, and they have tiny screws holding them in place. I managed to drop one of the screws into the belly of the drone, but luckily it popped out when I turned it over. You have to be careful, though.

I was going great guns on the project until I got to a part that I thought would be super-simple, transferring the landing gear from the old shell to the new shell. First off, those access doors on the gear are a pain to get off - not sure what the right way to do it is other than get something under them and pry hard. Especially in the front, there are electronics in there, so you have to be careful - I think I cracked a leg doing this. Once I did get the covers off, I found removing the hex screws to be another big chore. I was using a 1.5mm Allen wrench, which was really not the right tool for the job. I wound up ordering a nice screwdriver-style 1.5mm hex tool, and that made things much easier. DJI squirts some kind of rubbery material into the well, probably to hold the wires in place. I had to remove this stuff to get at the wires and screws.

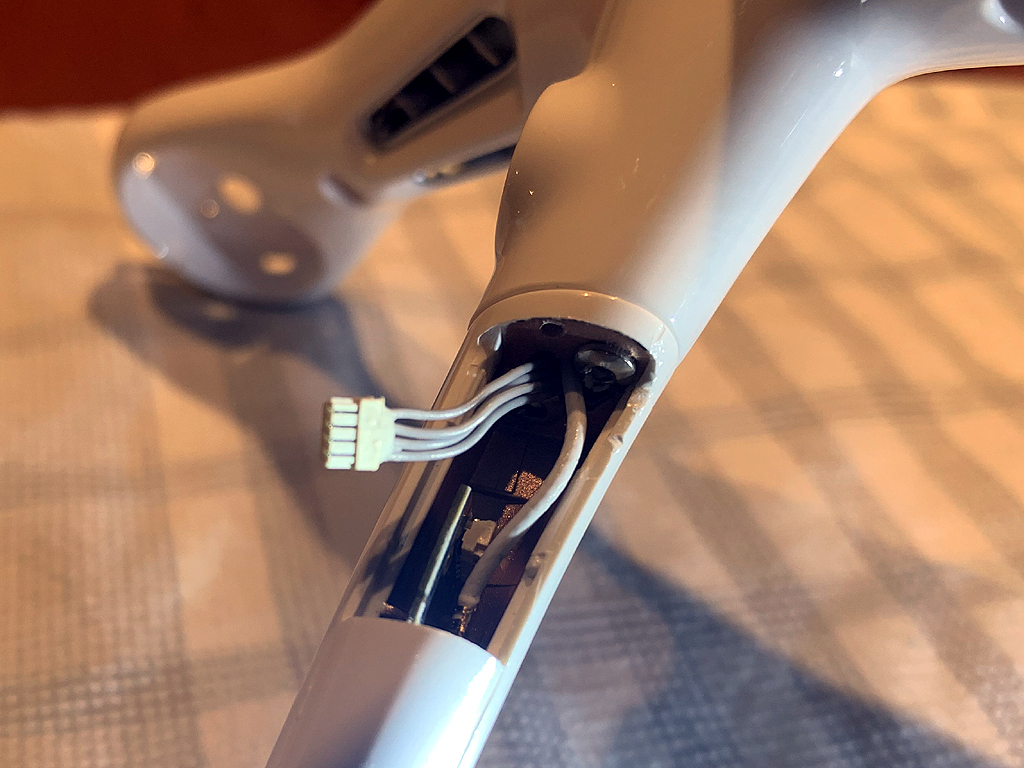

So what's inside the legs? On each of the front legs, you have both an antenna and a compass PC board. This means there is a single wire for the antenna, and a bundle containing four tiny wires for the compass. The rear legs have the antenna only, so there's a lot more room there.

Inside a Front Leg (compass cable is disconnected from the board at this point)

The next little surprise was to find that the four-wire bundle connecting the drone circuitry to the compass in the landing gear had a clip too big to feed down through the shell. Instead, you have to disconnect the tiny bracket on the compass inside the leg and feed it up. No fun at all, and this is where problems began. Once I mounted the new legs, I then tried to re-connect the cable to the compass circuit board. There is a wrong way to do this, and I managed to find it. Long story short, I damaged both the cable and the receptacle on one of the compass boards, but it wasn't immediately apparent. I got the drone entirely back together again, only to get a "compass disconnected" message on Compass 2 when I powered up. This meant another complete disassembly (uggh...), and ordering a $35 set of legs.

Compass Plug - Bottom Side (this side goes toward the PC board)

Compass Plug - Bottom Side (this side face away from the PC board)

There was some confusion over whether a P4P landing gear set would work on a P4A, but I found out the parts are interchangeable. I decided to cut into the damaged compass leg to get a better idea of how things went together, and found that I had indeed bent one of the contacts inside the receptacle. That would have been nearly impossible to fix, so good thing I went with new landing gear.

New Landing Gear Set:

New Landing Gear Set - Product Description:

Top View of Damaged Plug (landing gear top cut away, note bent contact on top)

After all this, I put the drone back together, and was rewarded with solid greens on the compass health window when I powered up. Whew! I took it out for a test flight before putting the light lenses and landing gear covers back on, and all was well. My other concern was that perhaps I'd messed up an antenna wire, but the range seems as good as before. I took it back in, and shot some hot glue into the space where the wires feed into the landing gear to hold them in place (this was to replace the material that had been in there originally from DJI). I then put the lenses back on, then the gear covers. The gear covers are much more difficult to put back on than you'd think; they have locating pins both at the top and bottom, and it's not clear how you'd be able to get these on as-is. I wound up snipping off the top mounting pins, and they seem secure enough. I have an extra set now in case one of them pops off, and perhaps using a super glue-type adhesive would help secure them.

So that's that. Big job, but I didn't have to send it out for repair, and my down time was minimized. I also saved money, as long as you don't factor in the time I spent. Total repair cost, including the hex driver I had to buy, was about $80 vs. the $200 quoted by one repair shop over the phone. If I had to do this over again I'd be able to do it in about a quarter of the time I spent on this first round. Let's hope it doesn't come to that.

Back in Business!

So, the root of my problems was stress cracks that developed on both rear arms of my drone. The drone is about 2 1/2 years old, and has never crashed or really even had a hard landing, so the cause is a mystery. It's either the material used in the plastic getting stressed over time, or my drone backpack exerting pressure in the wrong places. I might put out a separate post on that to see what thoughts people have. At any rate, the cracks didn't affect the way the drone handled, but they made me uneasy. Upon getting the thing apart, I found the cracks extended not only through the shell, but also through a ridge surrounding the vent hole.

Shell Crack:

I ordered a new lower shell from Amazon for $35 - be aware that the P4A has a unique lower shell, since it lacks the side and rear vision sensors of the P4P, so you can't use a P4P lower shell on a P4A unless you want empty holes in the shell. The first snag in the project came early - my new shell arrived damaged. I ordered another and returned the damaged one, a process that set me back a couple of days.

New Lower Shell:

The guy who did the following YouTube video did all the hard work - this is not my video, but it details a complete shell replacement on a Phantom 4 Pro. It was pretty much my bible for the project:

Again, the video shows a complete shell replacement, a much more involved task than just replacing the lower shell like I needed. I got lucky that my cracks stayed on the lower shell; otherwise, the motors need to be unsoldered and resoldered, which is apparently a chore.

The basic disassembly went OK, but once all the screws are removed, the shell is really tough to get apart. The videos will tell you to press in around tabs located on the bottom shell, but this didn't work well for me, and in the end, brute force had to be applied. I broke one of the locating tabs on the old lower shell doing this, but since it was going to be replaced, this wasn't an issue.

Drone in Pieces:

There are metal brackets to contain the gimbal cable and the antenna wires, and they have tiny screws holding them in place. I managed to drop one of the screws into the belly of the drone, but luckily it popped out when I turned it over. You have to be careful, though.

I was going great guns on the project until I got to a part that I thought would be super-simple, transferring the landing gear from the old shell to the new shell. First off, those access doors on the gear are a pain to get off - not sure what the right way to do it is other than get something under them and pry hard. Especially in the front, there are electronics in there, so you have to be careful - I think I cracked a leg doing this. Once I did get the covers off, I found removing the hex screws to be another big chore. I was using a 1.5mm Allen wrench, which was really not the right tool for the job. I wound up ordering a nice screwdriver-style 1.5mm hex tool, and that made things much easier. DJI squirts some kind of rubbery material into the well, probably to hold the wires in place. I had to remove this stuff to get at the wires and screws.

So what's inside the legs? On each of the front legs, you have both an antenna and a compass PC board. This means there is a single wire for the antenna, and a bundle containing four tiny wires for the compass. The rear legs have the antenna only, so there's a lot more room there.

Inside a Front Leg (compass cable is disconnected from the board at this point)

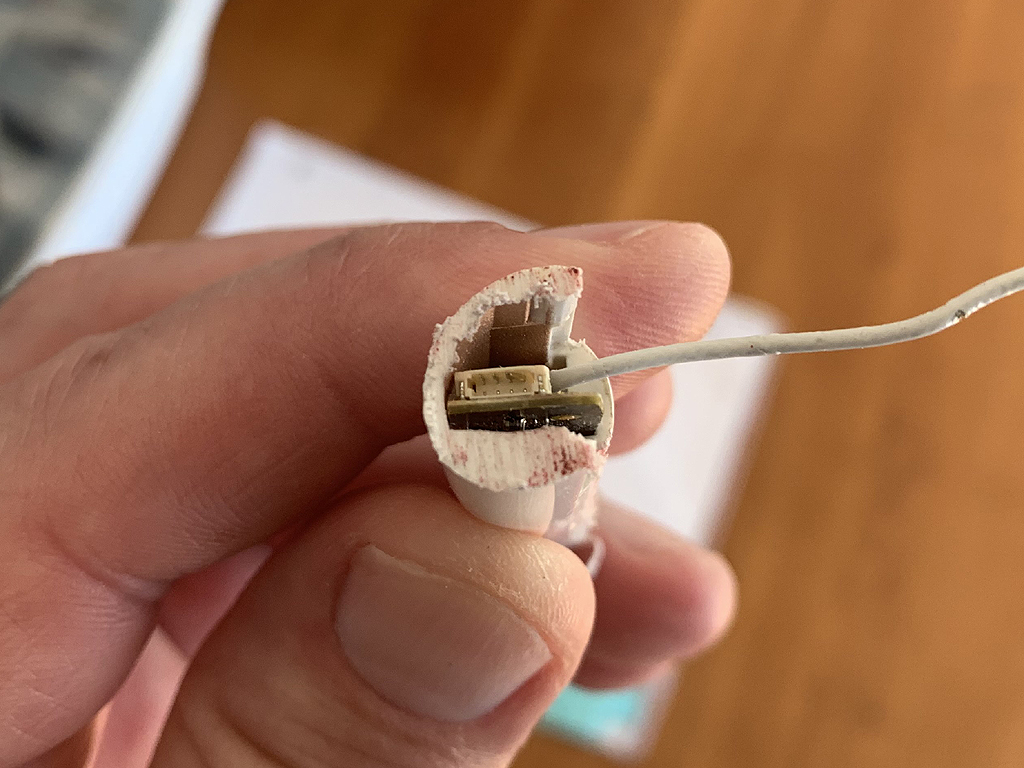

The next little surprise was to find that the four-wire bundle connecting the drone circuitry to the compass in the landing gear had a clip too big to feed down through the shell. Instead, you have to disconnect the tiny bracket on the compass inside the leg and feed it up. No fun at all, and this is where problems began. Once I mounted the new legs, I then tried to re-connect the cable to the compass circuit board. There is a wrong way to do this, and I managed to find it. Long story short, I damaged both the cable and the receptacle on one of the compass boards, but it wasn't immediately apparent. I got the drone entirely back together again, only to get a "compass disconnected" message on Compass 2 when I powered up. This meant another complete disassembly (uggh...), and ordering a $35 set of legs.

Compass Plug - Bottom Side (this side goes toward the PC board)

Compass Plug - Bottom Side (this side face away from the PC board)

There was some confusion over whether a P4P landing gear set would work on a P4A, but I found out the parts are interchangeable. I decided to cut into the damaged compass leg to get a better idea of how things went together, and found that I had indeed bent one of the contacts inside the receptacle. That would have been nearly impossible to fix, so good thing I went with new landing gear.

New Landing Gear Set:

New Landing Gear Set - Product Description:

Top View of Damaged Plug (landing gear top cut away, note bent contact on top)

After all this, I put the drone back together, and was rewarded with solid greens on the compass health window when I powered up. Whew! I took it out for a test flight before putting the light lenses and landing gear covers back on, and all was well. My other concern was that perhaps I'd messed up an antenna wire, but the range seems as good as before. I took it back in, and shot some hot glue into the space where the wires feed into the landing gear to hold them in place (this was to replace the material that had been in there originally from DJI). I then put the lenses back on, then the gear covers. The gear covers are much more difficult to put back on than you'd think; they have locating pins both at the top and bottom, and it's not clear how you'd be able to get these on as-is. I wound up snipping off the top mounting pins, and they seem secure enough. I have an extra set now in case one of them pops off, and perhaps using a super glue-type adhesive would help secure them.

So that's that. Big job, but I didn't have to send it out for repair, and my down time was minimized. I also saved money, as long as you don't factor in the time I spent. Total repair cost, including the hex driver I had to buy, was about $80 vs. the $200 quoted by one repair shop over the phone. If I had to do this over again I'd be able to do it in about a quarter of the time I spent on this first round. Let's hope it doesn't come to that.

Back in Business!