Hello Everyone,

Well, I'm at it again. Since I posted my adding sound to P2v mod, I've received several replies about a sound they are hearing in my video, of a possible BAD BEARING?

So,

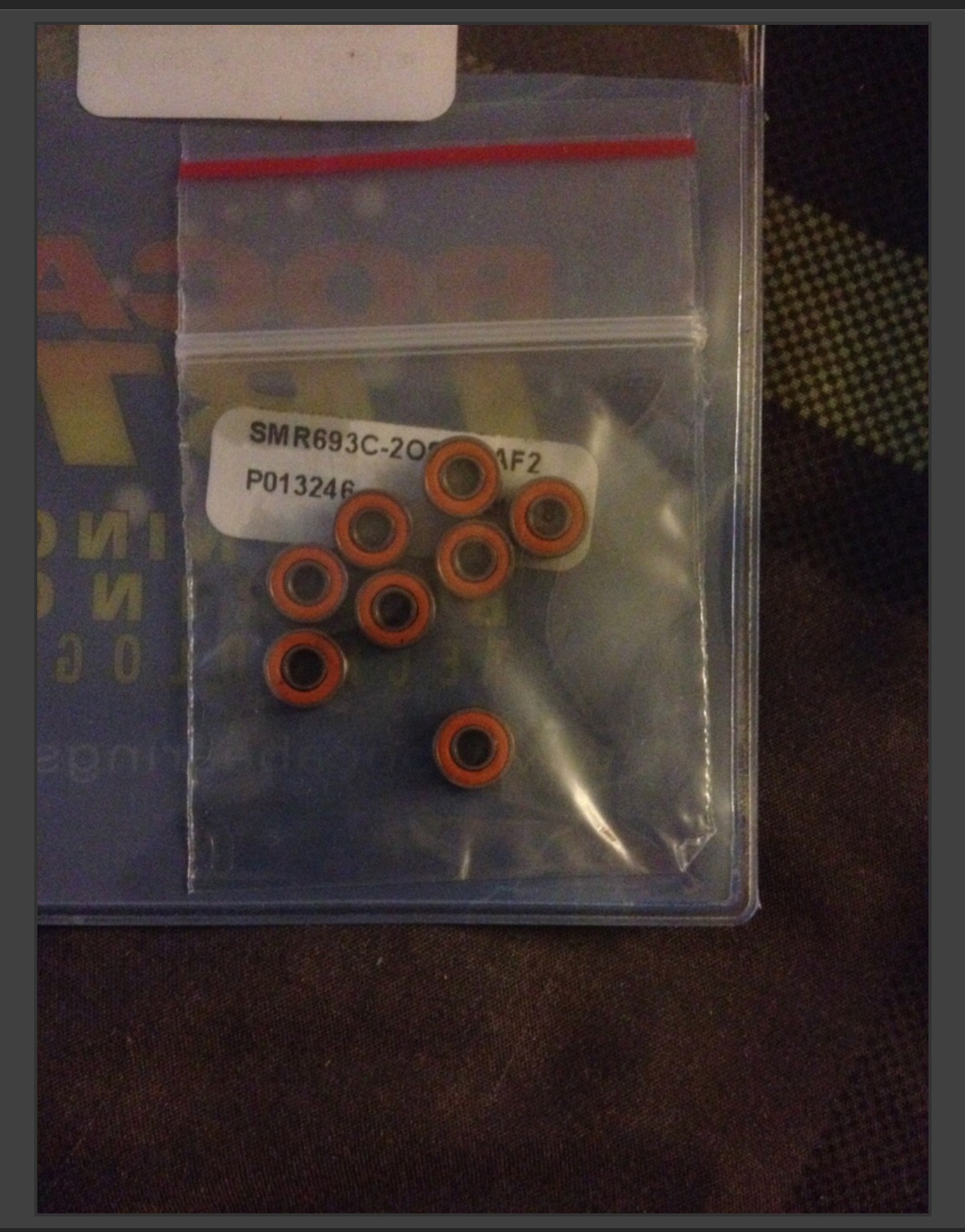

I decided, that must be my next MOD! New bearings! So I got ahold of a local business, named BOCA BEARINGS. I ordered 1 of 3 sets offered! They have a set that is steel bearings, steel shielded, high quality bearings ( econo version ) for $39.95set of 8, then set 2 is a higher quality ceramic bearing, steel races, shielding.

( mid grade very high quality ) for $62.95 set of 8, then they have the Top of the line, Orange seal, ceramic bearings ( super high quality bearing ) for $88.95

Bocabearings.com

I bought the super high quality ceramic ones, plus I bought their lightning oil/grease. ( lightening lube $14.95 ) For preventative maintenance.

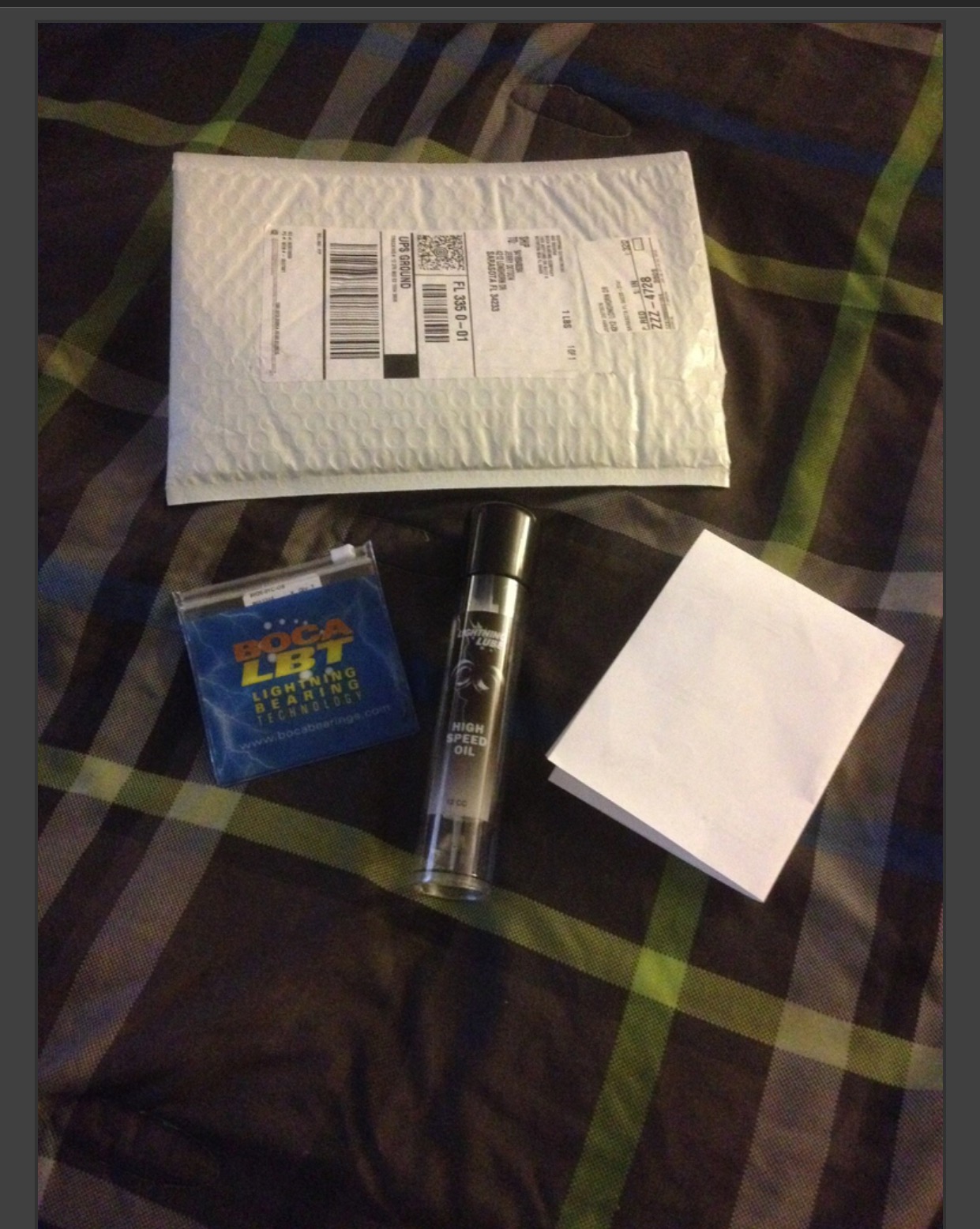

Here is the pictures of me opening the package.

( got Bearings x8, Lightening oil, and receipt )

BOCA Bearings

Bearing kit # H26-01C-OS. / Item # 23040

Lightning Lube high speed oil

Item # 13931

( bocabearings.com )

I will do pictures of the mod, and share with you, AS USUAL! Lol.

Take care, Fly safe!

J Dot

Well, I'm at it again. Since I posted my adding sound to P2v mod, I've received several replies about a sound they are hearing in my video, of a possible BAD BEARING?

So,

I decided, that must be my next MOD! New bearings! So I got ahold of a local business, named BOCA BEARINGS. I ordered 1 of 3 sets offered! They have a set that is steel bearings, steel shielded, high quality bearings ( econo version ) for $39.95set of 8, then set 2 is a higher quality ceramic bearing, steel races, shielding.

( mid grade very high quality ) for $62.95 set of 8, then they have the Top of the line, Orange seal, ceramic bearings ( super high quality bearing ) for $88.95

Bocabearings.com

I bought the super high quality ceramic ones, plus I bought their lightning oil/grease. ( lightening lube $14.95 ) For preventative maintenance.

Here is the pictures of me opening the package.

( got Bearings x8, Lightening oil, and receipt )

BOCA Bearings

Bearing kit # H26-01C-OS. / Item # 23040

Lightning Lube high speed oil

Item # 13931

( bocabearings.com )

I will do pictures of the mod, and share with you, AS USUAL! Lol.

Take care, Fly safe!

J Dot

Last edited: