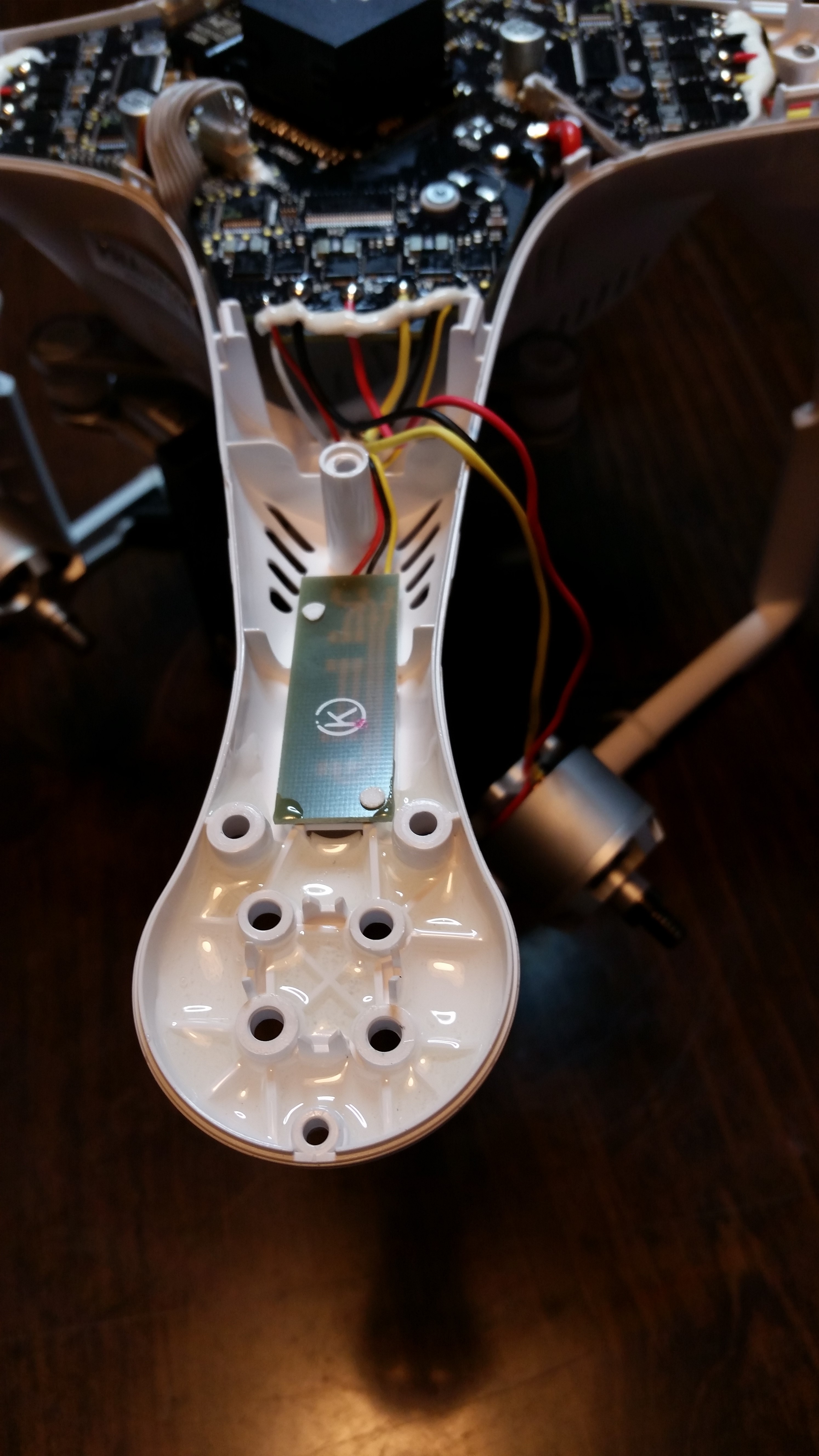

One of my beloved Phantom developed cracks the the usual spots. One way to deal with it is to install snap on/off prop guards using the guard base as reinforcement to the motor mount area. The proper way though aside from a purchase of a new shell and the hassle of a complete tear down is to coat epoxy in the motor mount bed. This not only strengthens the bed area it will also help absorb the high frequency vibrations that I feel weaken the plastic used in manufacturing. When laying the epoxy take care not to get any on the motor mount posts or the motor guides that keep the motor straight. Also don't get epoxy on the edges of the shell where the lip edges join in a groove.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shell crack repair method.

- Thread starter GrammatonxXXxCleric

- Start date

UV cure adhesives (Bondic being one well known brand) will likely give better performance than two

Part epoxy in this application. I found epoxy to have less adhesion strength than I would have expected, I think the phantom shell must be made out of recycled milk bottles.

Part epoxy in this application. I found epoxy to have less adhesion strength than I would have expected, I think the phantom shell must be made out of recycled milk bottles.

- Joined

- Nov 16, 2015

- Messages

- 876

- Reaction score

- 337

- Age

- 65

I agree the plastic is the worst choice I've EVER seen. Brittle, although lightweight there had to be another type they could have used. As for the glue type used, as long as the surface is cleaned ( I use 90% alcohol) and roughened lightly it should be fine for this use.The mold release agent used in injection molding is not consistant with time. As each shell is produced if the operator does not re-apply the release compound there will be less in the mold. The compound will interfere with the epoxy's adhesion factor. I am not familiar with "Bondic" but as long as it's strong, a bit flexible it should work. I'll keep my eyes on the stick durability but I imagine it'll work.UV cure adhesives (Bondic being one well known brand) will likely give better performance than two

Part epoxy in this application. I found epoxy to have less adhesion strength than I would have expected, I think the phantom shell must be made out of recycled milk bottles.

I'm my view this will not be a factor. When the motors spin with props there should be more than enough air flowing. And The bottom of the motor is still open to flow in my drone after installing them. I'd guess the epoxy layer is 1/32 or less thick in most spots.Yes, good job no question. The only isssue I migh suggest is that with filling all the available area between the motor mounting bosses airflow through the motors might be restricted.

Fair enough- hard to see from the image.I'm my view this will not be a factor. When the motors spin with props there should be more than enough air flowing. And The bottom of the motor is still open to flow in my drone after installing them. I'd guess the epoxy layer is 1/32 or less thick in most spots.

Spot on G~Cleric.  I'm going to stuff the DJI Return~ Refurb ~ Recycle junk approach and have a go with your idea. The Standard DJI Prop Guards only have 2 mount holes and would only brace half of the arm end. Your idea though has convinced me to kill-drill and Dremel grind the cracks then paint the insides with some sort of UK equivalent epoxy. If anyone in UK has any recommendations apart from the usual Araldite 2x Part Epoxy. Nothing against Araldite, just checking on any alternatives with a tried and tested use.

I'm going to stuff the DJI Return~ Refurb ~ Recycle junk approach and have a go with your idea. The Standard DJI Prop Guards only have 2 mount holes and would only brace half of the arm end. Your idea though has convinced me to kill-drill and Dremel grind the cracks then paint the insides with some sort of UK equivalent epoxy. If anyone in UK has any recommendations apart from the usual Araldite 2x Part Epoxy. Nothing against Araldite, just checking on any alternatives with a tried and tested use.

I'll take the gamble on my cracked P3/4 & P3Pro with light use and fix it myself against the DJI Fandango. I'll try the above and also add the bracing bottom plates that I've seen advertised. If it comes to it, I will buy replacement body shells and do it to it/ them.

I am not going to lose up to 6 weeks of what summer flying weather we might get over here. One minute sunshine blazing down, drizzle and thunderstorms the next.

Now where did I put the Dremel Grinding disks?!

I'll take the gamble on my cracked P3/4 & P3Pro with light use and fix it myself against the DJI Fandango. I'll try the above and also add the bracing bottom plates that I've seen advertised. If it comes to it, I will buy replacement body shells and do it to it/ them.

I am not going to lose up to 6 weeks of what summer flying weather we might get over here. One minute sunshine blazing down, drizzle and thunderstorms the next.

Now where did I put the Dremel Grinding disks?!

Oso

Premium Pilot

As @With The Birds noted earlier, Bondic has been recommended many dozens of times in the last couple of years. Note that I have not used it personally. I've only read about here on the forum in most "crack" threads. It seems to be recommended so often that it's worth being on your list of potential alternative choices.If anyone in UK has any recommendations apart from the usual Araldite 2x Part Epoxy. Nothing against Araldite, just checking on any alternatives with a tried and tested use.

Thanks Oso. Had a quick look and at 4g per refill x 8 x £10 Plus the UV activator plus delivery, it won't leave much change out of £100. That's about the same price I'd expect to pay for 2 new replacement P3 Body Shells. I'm probably being overly generous but just an idea for 2x P3's which would need 8 motor mounts sorted.

Note that in Rip Off UK, the $ -> £ conversion is just the currency symbol. Whether it is Apple, DJI or Bondic outlets, then 'they' just bypass the currency exchange rate. It is so much easier and no chance of mathematical errors.

Whether it is Apple, DJI or Bondic outlets, then 'they' just bypass the currency exchange rate. It is so much easier and no chance of mathematical errors.

No wonder we cry when reading that Cost-Co are doing P3kits forsay .. $500 ... the equivalent bargain is £500 which translates back to around $640. Someone is making big money for old rope.

Has anyone tried the Super Glue ~ Baking Powder cunning plan? Either with a Phantom or any other similar type of repair. Could be a cheaper method than £100.

Remember, you are talking to a tight fisted Scotsman here!

Note that in Rip Off UK, the $ -> £ conversion is just the currency symbol.

No wonder we cry when reading that Cost-Co are doing P3kits forsay .. $500 ... the equivalent bargain is £500 which translates back to around $640. Someone is making big money for old rope.

Has anyone tried the Super Glue ~ Baking Powder cunning plan? Either with a Phantom or any other similar type of repair. Could be a cheaper method than £100.

Remember, you are talking to a tight fisted Scotsman here!

- Joined

- Mar 7, 2017

- Messages

- 51

- Reaction score

- 18

- Age

- 63

I purchased a phantom 3 advanced used on ebay, excellent condition, it came with a set of the snap on prop gaurds with longer motor bolts, they appear to have never been installed, I attached the snap-on devices under each motor, I am not sure if I will ever use the gaurds but I believe the plastic part the gaurds snap to will protect the plastic from cracking, I'm thinking that not having the screw head putting all that force on the attachment point will help, now the pressure is distributed because of the snap-on guard.

Has anyone tried the Super Glue ~ Baking Powder cunning plan? Either with a Phantom or any other similar type of repair. Could be a cheaper method than £100.

Remember, you are talking to a tight fisted Scotsman here!

I did on a P2V with cracks, worked fine and it flew with no issues.

Thanks Crash. That one is going to the top of my list.

I have plenty Baking Powder but the scones will have to wait until next week.

I have plenty Baking Powder but the scones will have to wait until next week.

Thanks Richard. I'll check the e-bay and Amazon suppliers and see if there is a UK or Euro supplier.

Cheers, Alan.

Cheers, Alan.

That looks extra good..... The adhesive thickness is nowhere near what it appeared to be in the earlier shots.Here is a picture taken after motor installation with a different camera.

View attachment 82980

- Joined

- Feb 15, 2016

- Messages

- 366

- Reaction score

- 81

- Age

- 24

A few months ago I had a small crack develop and since I was still under warranty, I didn't want to open it up but didn't want the send it in either since I have already dealt with DJI warranty services twice. I picked up some Bondic and it worked great for patching a crack on the surface of the shell. It held well and stopped the crack from spreading after many hours of flight.

A couple weeks ago, now I'm out of warranty so I took everything apart and filled in the motor mounts with two part plastic epoxy by locktite, had no issues with it.

A couple weeks ago, now I'm out of warranty so I took everything apart and filled in the motor mounts with two part plastic epoxy by locktite, had no issues with it.

- Joined

- Mar 2, 2017

- Messages

- 97

- Reaction score

- 18

- Age

- 68