The Real Carbon Fiber Cloth Plain weave kit and epoxy resin

I would get a batch of that, Scuff the surface

http://www.amazon.com/Scratch-Brush-Fiberglass-Colors-vary/dp/B0019V18D2/ref=pd_sim_263_5?ie=UTF8&refRID=0R5RRSDNPXJT9B0XEWNN&dpID=21cZx0a5RzL&dpSrc=sims&preST=_AC_UL160_SR160,160_

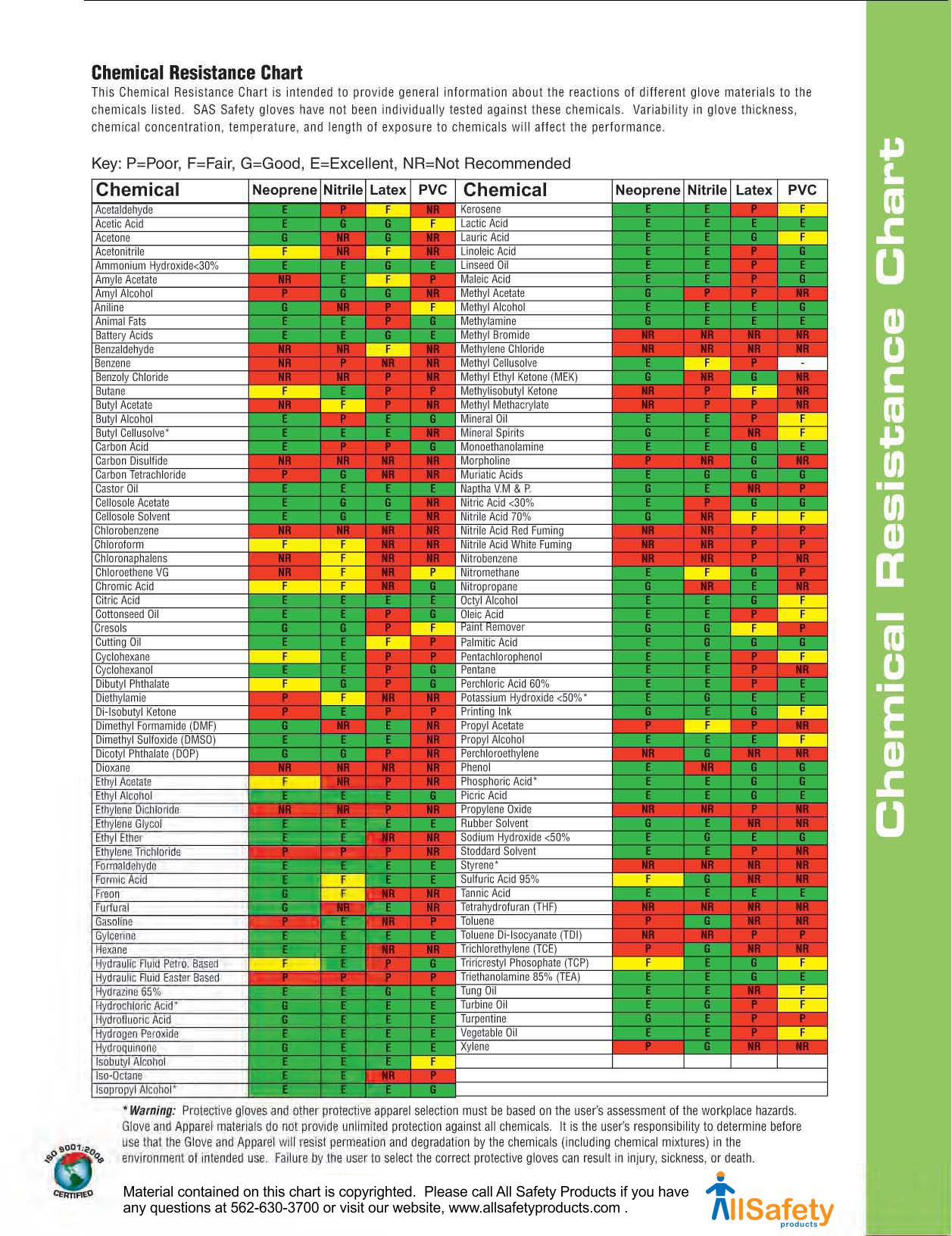

Clean the thing real well with MEK, Make sure you only clean the surface, it will etch and could dissolve the plastic. I just checked and it will eat the plastic so be careful to only clean the surface. Let the MEK evaporate in a clean environment for a couple hours.

Cut you some small patches of the CF cloth. Mix a small amount of the resin, mix precisely very precisely. Put down a thin but even layer of the epoxy (make sure to make it slightly larger than your CF patches) and let get tacky to the touch, time can vary depending on how well you measured the resin and hardener, keep testing until a nice fingerprint remains. Put down the fiber patch on the resin. Mix resin/hardener, put on top of patch and repeat the entire process until you are satisfied, 3-4 layers will probably be fine. 24-48 hours later you have a permanent fix.

I laid two layers of that ebay fiber under the weight of a book in a ziplock bage it measured 0.05" Just measured the dry CF, if they sent the same 3Kplain weave, it is 0.01" thick.

You really should have nitrile gloves and a respirator, good ventilation.

Not easy but a good fix for sure.