my idea was to use the PWM (what you call a servo signal) pulled directly off of the main board (4 per board, obviously) and have them run to completely separate ESC's.. each which has it's own feedback sensing. The power isn't really an issue because I had the thought of having one battery for the controller and possibly a dedicated battery for each ESC/motor. Maybe I'm crazy here, but to me, it seems that the controller shouldn't care what ESC it is connected to. It outputs a constant frequency signal to drive a motor controller which in turn creates a "variable" frequency (which is also the same frequency all of the time, just varying duty cycle and total "phase time" to create the same effect as different frequencies to drive the MOSFET's. The only place the frequency changes is after the MOSFET's (the effect of the VFD circuitry is a differing signal consisting of pulses of varying width to create the effect of a rising and falling differential in voltage).

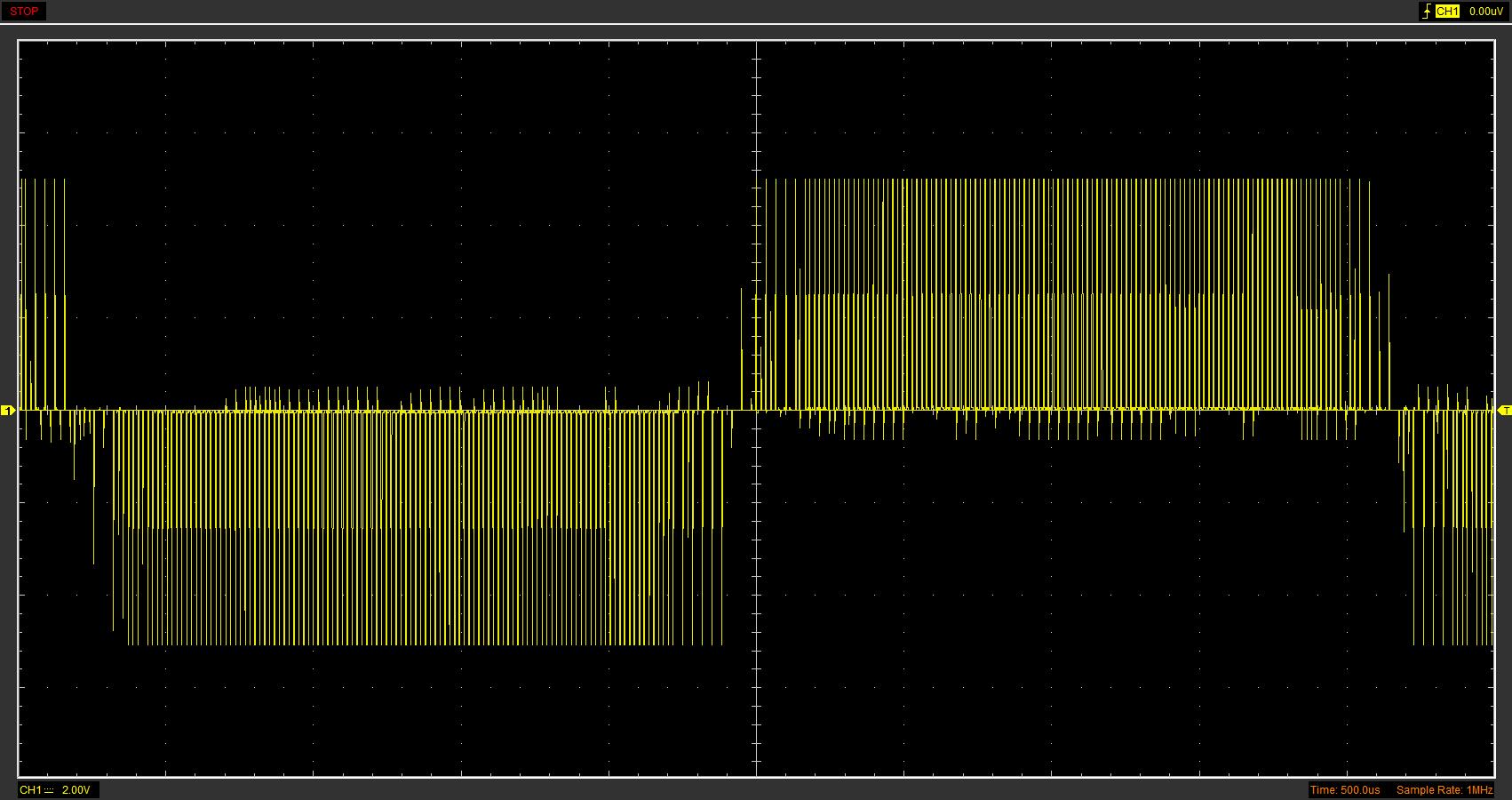

No, between the flight controller and the motor controller IC. Which is a constant frequency... However, the duty cycle changes, hence PWM (Pulse Width Modulation)

Flight Controller>---(test here)--->motor controller>---(32 bit communication)--->3 Phase driver>---(first "variable" frequency)--->MOSFET's>------>Motors

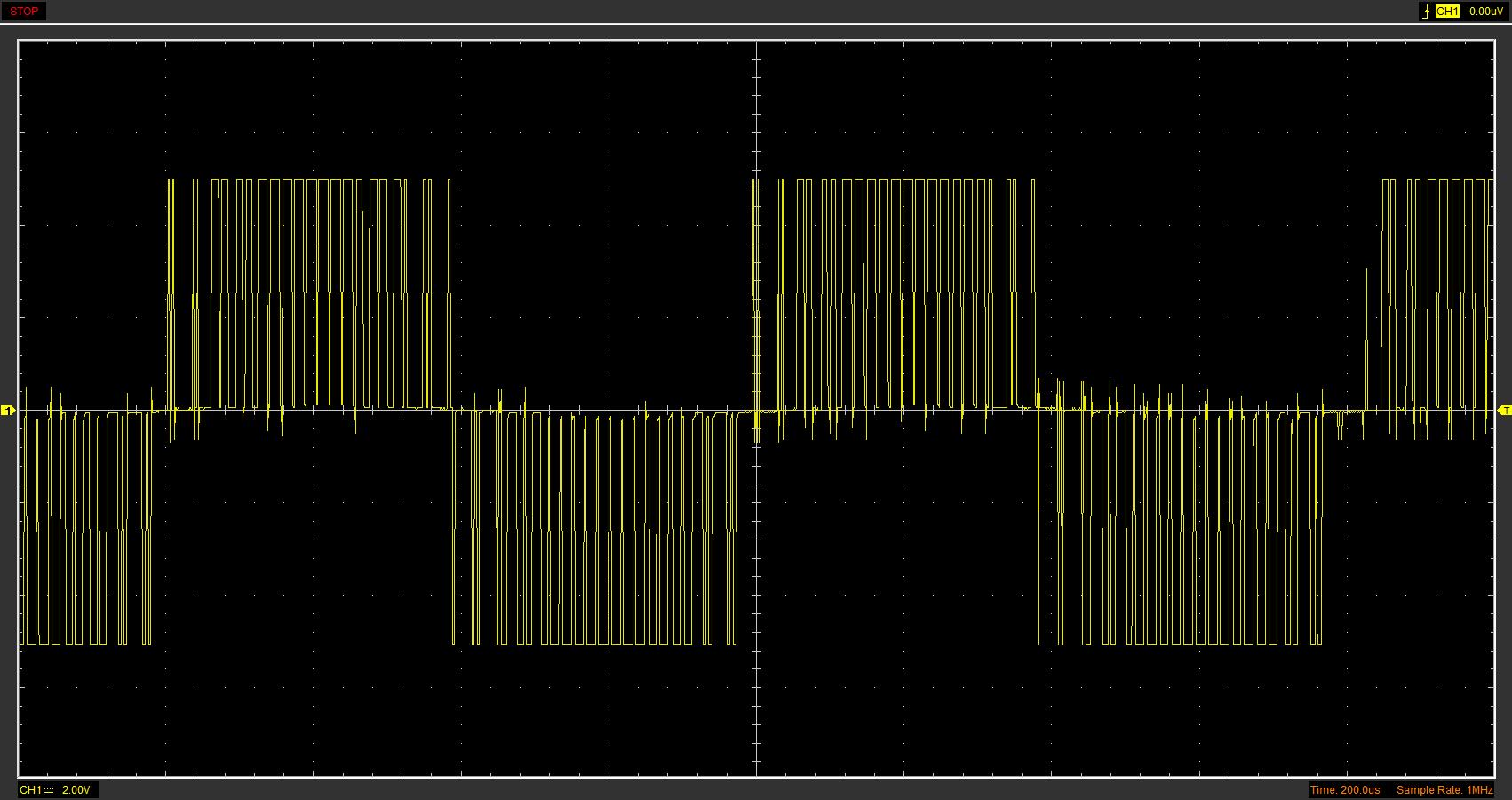

For all intents and purposes, an ESC is nothing more than a VFD. It creates a "sine wave" depending on the frequency dictated by the driver IC, through the motor controller IC, and originating at the flight controller. At low speed or throttle, there is a lot of pulses per half wave, but they have shorter duty cycles. When driving an inductive load, this has the same effect as a low frequency / low amplitude sine wave. The duty cycle always starts off low, rises up, and then falls again before each individual winding is driven the same again but in reversed polarity.

Then, when at full "throttle" this all happens again but faster with longer pulses (but fewer of them since the actual pulse frequency stays the same) creating the effect of a high frequency / high amplitude sine wave thus driving the motor faster.

I believe that if we were to hijack the PWM signal before it goes into the motor controller IC and route it to standalone ESC's, it would/should work. performing a simple battery mod would allow us to supply power to these circuits. Hell, if we parallel extra batteries to the intelligent batteries of the Phantom, we could even have the intelligent battery circuitry monitor overall voltages for us through it's UART interface.