After 7 flights I have cracks under 3 of my motor mounts. P3P is just 2 weeks old. Is this just the way it is going to be? Get cracks send it back and wait? Any good thoughts on self repairs or don't buy another one? DJI if you're reading, pick a finger, I did not spend my hard earned cash to have to play with customer service (word is yours sucks) are we going to put up with this or start recommending not to buy DJI Phatoms?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,787

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

Most people do not have this problem. For those that do, DJI is offering to repair them for free. Considering they already made design changes to resolve this potential issue, I don't think there is much more we can ask of them.

It's simple, the cracks are because the plastic areas that endure the stress is too thin. Sending it back will do 3 things.

1. Get you a new shell.

2. Trim several weeks of the warranty of your phantom and remove it from your hands eliminating time you can fly.

3. Provide you with a new shell and the opportunity to repeat steps 1 & 2

Solution for $20.00 and the satisfaction of DIY.

Plast-Aid - Plast-aid® multi-purpose repair plastic for your repair solutions.

I have applied it to all motor mount areas before I ever powered it up, Ok so I have voided my warranty, No biggie. All the parts needed for a repair or replacement of parts are available in the US anyway.

Reinforce the Mount areas with what I have found is just short of a Miracle product.

There is no need to fear, the solution is here.

I just wanted to share with everyone the once and for all solution for $20.00

There is a fantastic product called Plast-Aid available from the manufacturer or on Amazon

This produce is a 2 part mix, it is not epoxy or glue. It is Plastic that is as strong as steel.

In fact it is so strong a piece 1/4 inch thick 2 inches long can not be broken by bare hands...

The components are a powder and a liquid. Pour powder in a supplied cup, pour in enough liquid for it to be saturated...

Stir it to mix well and pour it while it is still thin into the area of the motor mount so that it is up to the level of the mount base area.

Vibrate it by hand a little so the liquid plastic levels itself and flows into all the areas around the mounts.

You will have about 2 minutes before it starts to become thick so do it quickly.

Once it begins to become thick use a tooth pick to scoop up some and place it behind the body mount hole

to provide more bracing and strength. wait about 8 minutes and it will be like puddy where you can then press it into shape to refine the application as needed.

After about 10 minutes leave it alone and it will begin to get hot and start bonding to the shell material.

After about 15 minutes it will cool down and become hard as steel and totally bonded to your shell. It will at this point be part of the shell, not just

adheared like glue but actually part of the shell.

Over 100 flights and not one hint of a crack at all, not even the slightest.

1. Get you a new shell.

2. Trim several weeks of the warranty of your phantom and remove it from your hands eliminating time you can fly.

3. Provide you with a new shell and the opportunity to repeat steps 1 & 2

Solution for $20.00 and the satisfaction of DIY.

Plast-Aid - Plast-aid® multi-purpose repair plastic for your repair solutions.

I have applied it to all motor mount areas before I ever powered it up, Ok so I have voided my warranty, No biggie. All the parts needed for a repair or replacement of parts are available in the US anyway.

Reinforce the Mount areas with what I have found is just short of a Miracle product.

There is no need to fear, the solution is here.

I just wanted to share with everyone the once and for all solution for $20.00

There is a fantastic product called Plast-Aid available from the manufacturer or on Amazon

This produce is a 2 part mix, it is not epoxy or glue. It is Plastic that is as strong as steel.

In fact it is so strong a piece 1/4 inch thick 2 inches long can not be broken by bare hands...

The components are a powder and a liquid. Pour powder in a supplied cup, pour in enough liquid for it to be saturated...

Stir it to mix well and pour it while it is still thin into the area of the motor mount so that it is up to the level of the mount base area.

Vibrate it by hand a little so the liquid plastic levels itself and flows into all the areas around the mounts.

You will have about 2 minutes before it starts to become thick so do it quickly.

Once it begins to become thick use a tooth pick to scoop up some and place it behind the body mount hole

to provide more bracing and strength. wait about 8 minutes and it will be like puddy where you can then press it into shape to refine the application as needed.

After about 10 minutes leave it alone and it will begin to get hot and start bonding to the shell material.

After about 15 minutes it will cool down and become hard as steel and totally bonded to your shell. It will at this point be part of the shell, not just

adheared like glue but actually part of the shell.

Over 100 flights and not one hint of a crack at all, not even the slightest.

- Joined

- Sep 12, 2015

- Messages

- 128

- Reaction score

- 34

I feel your frustration. I had a crack on my unit after 7 flights also

And guess what... my unit was just sent back to me from DJI for repairs of cracks!

I almost want to try and sue somehow and get my money back!

Martin, we shouldn't have to void our warranty just to insure not to get these cracks that are obviously design flaws.

And guess what... my unit was just sent back to me from DJI for repairs of cracks!

I almost want to try and sue somehow and get my money back!

Martin, we shouldn't have to void our warranty just to insure not to get these cracks that are obviously design flaws.

The legal costs far outweigh the benefits of a suit to recover your money. That would be a no win venture.I feel your frustration. I had a crack on my unit after 7 flights also

And guess what... my unit was just sent back to me from DJI for repairs of cracks!

I almost want to try and sue somehow and get my money back!

- Joined

- Sep 12, 2015

- Messages

- 128

- Reaction score

- 34

Considering they already made design changes to resolve this potential issue, I don't think there is much more we can ask of them.

We shouldn't ask anything more of them?

Really?

You're funny.

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,787

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

Just note that if you do attempt to fix the shell yourself and fail, DJI will probably not replace it for free then. You might void other parts of the DJI warranty by dissembling the shell too.

Thanks for this idea will try on next P3It's simple, the cracks are because the plastic areas that endure the stress is too thin. Sending it back will do 3 things.

1. Get you a new shell.

2. Trim several weeks of the warranty of your phantom and remove it from your hands eliminating time you can fly.

3. Provide you with a new shell and the opportunity to repeat steps 1 & 2

Solution for $20.00 and the satisfaction of DIY.

Plast-Aid - Plast-aid® multi-purpose repair plastic for your repair solutions.

I have applied it to all motor mount areas before I ever powered it up, Ok so I have voided my warranty, No biggie. All the parts needed for a repair or replacement of parts are available in the US anyway.

Reinforce the Mount areas with what I have found is just short of a Miracle product.

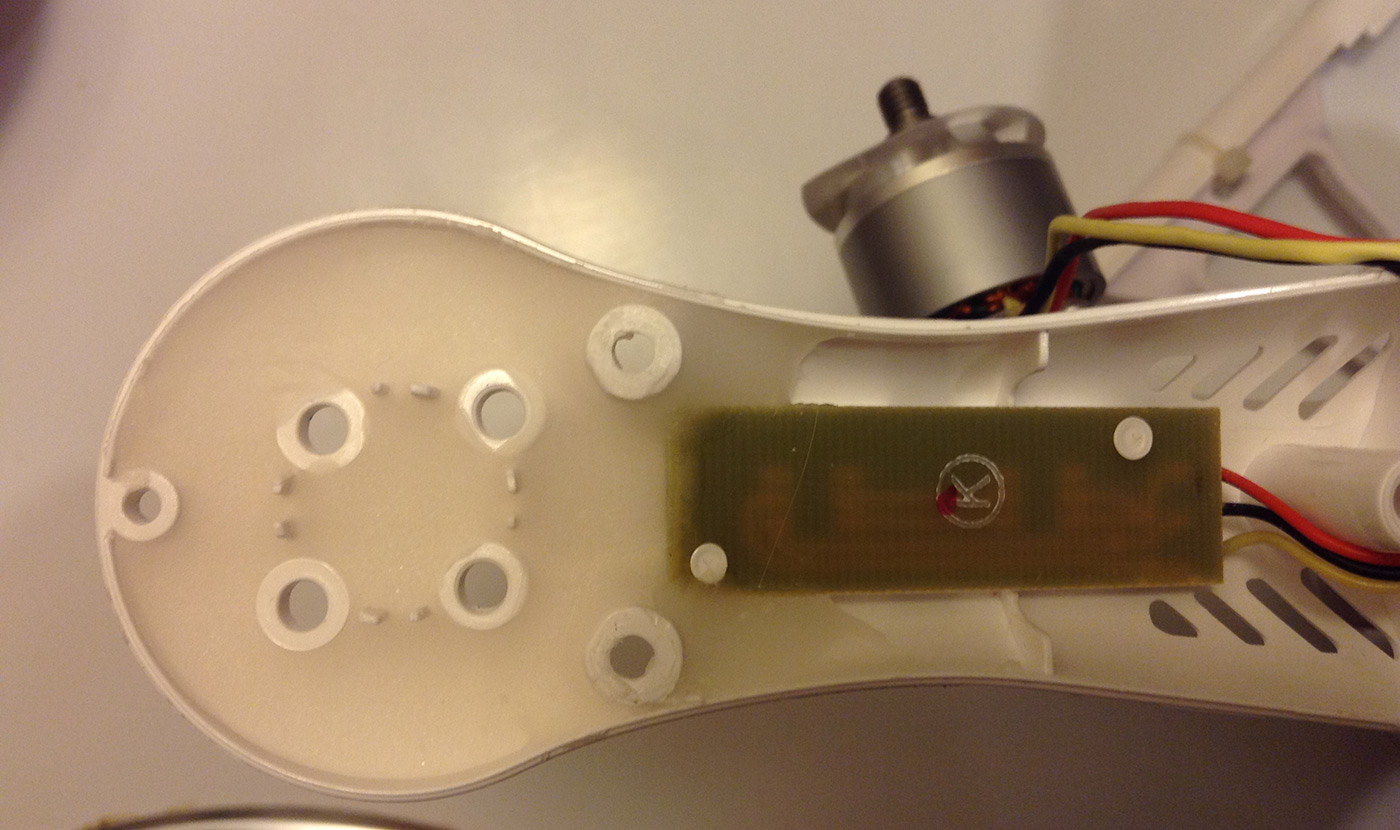

View attachment 34677

There is no need to fear, the solution is here.

I just wanted to share with everyone the once and for all solution for $20.00

There is a fantastic product called Plast-Aid available from the manufacturer or on Amazon

This produce is a 2 part mix, it is not epoxy or glue. It is Plastic that is as strong as steel.

In fact it is so strong a piece 1/4 inch thick 2 inches long can not be broken by bare hands...

The components are a powder and a liquid. Pour powder in a supplied cup, pour in enough liquid for it to be saturated...

Stir it to mix well and pour it while it is still thin into the area of the motor mount so that it is up to the level of the mount base area.

Vibrate it by hand a little so the liquid plastic levels itself and flows into all the areas around the mounts.

You will have about 2 minutes before it starts to become thick so do it quickly.

Once it begins to become thick use a tooth pick to scoop up some and place it behind the body mount hole

to provide more bracing and strength. wait about 8 minutes and it will be like puddy where you can then press it into shape to refine the application as needed.

After about 10 minutes leave it alone and it will begin to get hot and start bonding to the shell material.

After about 15 minutes it will cool down and become hard as steel and totally bonded to your shell. It will at this point be part of the shell, not just

adheared like glue but actually part of the shell.

Over 100 flights and not one hint of a crack at all, not even the slightest.

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,787

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

How do you know if your getting a newer versionWe shouldn't ask anything more of them?

Really?

You're funny.

How do you know if your getting the new version from store? Not trying to be funny I pissed.We shouldn't ask anything more of them?

Really?

You're funny.

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,787

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

Ask the store before you buy it. Here are the differences:How do you know if your getting the new version from store?

New vs. Old Motors:

Old Motors vs. New Ones | DJI Phantom Forum

New vs. Old Shell:

How to tell if you have old shell or new... | DJI Phantom Forum

- Joined

- Sep 12, 2015

- Messages

- 128

- Reaction score

- 34

What's so funny about that?

The jokes that you tell.

...You are joking right?

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,787

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

No, sir.The jokes that you tell.

...You are joking right?

It is a joke and not only DJIs attitude that should retract all the defective product it is people's attitude trying to discredit the askAfter 7 flights I have cracks under 3 of my motor mounts. P3P is just 2 weeks old. Is this just the way it is going to be? Get cracks send it back and wait? Any good thoughts on self repairs or don't buy another one? DJI if you're reading, pick a finger, I did not spend my hard earned cash to have to play with customer service (word is yours sucks) are we going to put up with this or start recommending not to buy DJI Phatoms?

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,787

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

Unfortunately, it would be impossible for DJI to know which products are defective. Most people don't have this problem, so it would be a huge waste of time and money to replace the shell on every Phantom that has the original shell.It is a joke and not only DJIs attitude that should retract all the defective product

It is a joke and not only DJIs attitude that should retract all the defective product it is people's attitude trying to discredit the ask

Could you please show us a copy of your purchase. ( Without private info thank you. ) registration may be a good thing after all.

This will allow us to filter. ( Please ) don't say you can't if you can afford to buy this Item you should be able too.

Thank you Sir.

- Joined

- Jan 29, 2015

- Messages

- 341

- Reaction score

- 77

What's so funny about that?

The part that I think was funny was your inference that consumers shouldn't expect a quality product that doesn't crack for virtually no reason. I remember a time when you could buy 10 or more complete plastic model kits for what DJI charges for one replacement shell. They were almost indestructible and they were only glued together with plastic cement. Maybe DJI should let Revell give them a quote for supplying the shells. As I have mentioned in other posts, of my four Phantoms I have had three of them develop bad cracks around the motor mounts requiring shell replacements. When I replaced them, I used a high quality epoxy to beef up the area around the motor mount holes. So far that seems to have solved that problem. I think the only reason my P3P doesn't have any cracks is that I haven't flown it more than 7 times. It is one of the original pre-order ones. But now that I finally have a working Flytrex in it, I will be flying it a lot more. Maybe I will have your luck and it will last a long time.

Excuse me? Come again Sir i dont follow u. Put up my invoice for your leisure to to filter what? And who are you and what is your role? By the way u r off topic.Could you please show us a copy of your purchase. ( Without private info thank you. ) registration may be a good thing after all.

This will allow us to filter. ( Please ) don't say you can't if you can afford to buy this Item you should be able too.

Thank you Sir.

Hear hear! Bravo.The part that I think was funny was your inference that consumers shouldn't expect a quality product that doesn't crack for virtually no reason. I remember a time when you could buy 10 or more complete plastic model kits for what DJI charges for one replacement shell. They were almost indestructible and they were only glued together with plastic cement. Maybe DJI should let Revell give them a quote for supplying the shells. As I have mentioned in other posts, of my four Phantoms I have had three of them develop bad cracks around the motor mounts requiring shell replacements. When I replaced them, I used a high quality epoxy to beef up the area around the motor mount holes. So far that seems to have solved that problem. I think the only reason my P3P doesn't have any cracks is that I haven't flown it more than 7 times. It is one of the original pre-order ones. But now that I finally have a working Flytrex in it, I will be flying it a lot more. Maybe I will have your luck and it will last a long time.

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 9

- Views

- 3K

- Replies

- 16

- Views

- 3K